39

Calculate the piston-to-piston pin clearance.

SERVICE LIMIT: 0.02 mm

Measure the connecting rod small end I.D.

SERVICE LIMIT: 15.06 mm

PISTON INSTALLTION

PISTON RING INSTALLATION

Clean the piston ring grooves thoroughly and install

the piston rings with the marks facing up.

NOTE: Don’t interchange the top and second rings.

Avoid piston and piston ring damage during

installation.

Space the piston ring end gaps 120 degrees apart.

Summary of Contents for XOR 125

Page 6: ...5...

Page 20: ...19 14...

Page 43: ...42 CHAPTER 4 FUEL AND LUBRICATION SYSTEM CONTENTS FUEL SWITCH CARBURETOR...

Page 64: ...63 3 Disconnect throttle cable and oil pump cable 4 Remove rear brake cable adjusting nut...

Page 91: ...90 WIRE CABLE AND BRAKE HOSE ROUTING...

Page 92: ...91 carburetor...

Page 93: ...92...

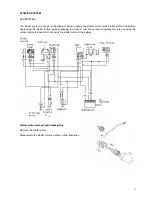

Page 94: ...93 Ignition coil Starting relay CDI HORN POWER SWITCHH...

Page 96: ...95...