26

4.

Do not allow dirt, pitch or gum to build up on the table, blade, guide/thrust bearings. Clean as needed with

gum and pitch remover.

Note: Do not immerse the bearings in the gum and pitch remover.

5.

To prevent rust and from forming on the unpainted cast iron of the table, and so that the wood slides easily while

cutting, apply a light coating of paste wax or use regular applications of any after-market surface protectant or

rust inhibitor.

REPLACING THE BANDSAW BLADE

The blade should be replaced when worn out.

Refer to the following symptoms to determine whether or not it is time to replace the blade:

- It is not cutting as fast.

- It is not able to follow a cutting line as it used to.

REQUIRED MAINTENANCE

REPLACING THE UPPER / LOWER BLADE GUIDES AND THRUST BEARINGS

Bearings should be verified each time the blade is replaced.

Check if they turn well. If not, the blade will get stuck or jam-

med between them and will wear prematurely.

To replace the upper/lower blade guides, proceed as follows:

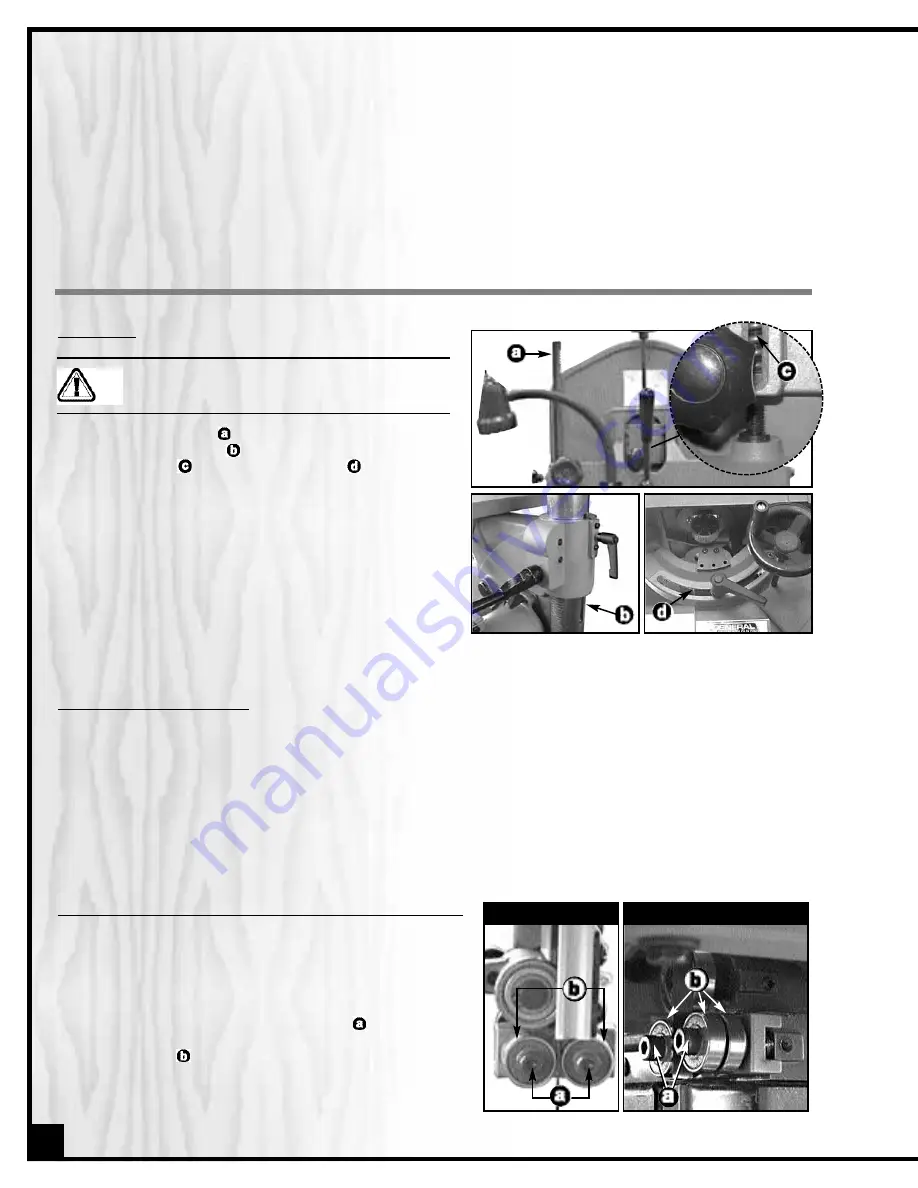

1.

Loosen and remove the two Allen bolts

, using the sup-

plied 5 mm Allen key. Removing the two bolts will free the

blade guides

.

2.

Replace the blade guides with new ones and tighten

with the two Allen bolts.

LOWER BLADE GUIDES

UPPER BLADE GUIDES

LUBRICATION

Disconnect machine from power source, before

performing any lubrication or maintenance.

Keep the blade guard

and upper frame height adjust-

ment rack and pinions

as well as the blade tension

adjustment screw

and the table trunnion

well greased

and free of dust or debris.

Clean and remove dust, debris, and old grease after every

10-15 hours of use. After cleaning, reapply grease as need-

ed. (Use any all purpose grease.)

The motor and all bearings are sealed and permanently

lubricated – no further lubrication is required. No other part

of this bandsaw needs lubrication.

Summary of Contents for 90-200 M1

Page 39: ...39 NOTES...