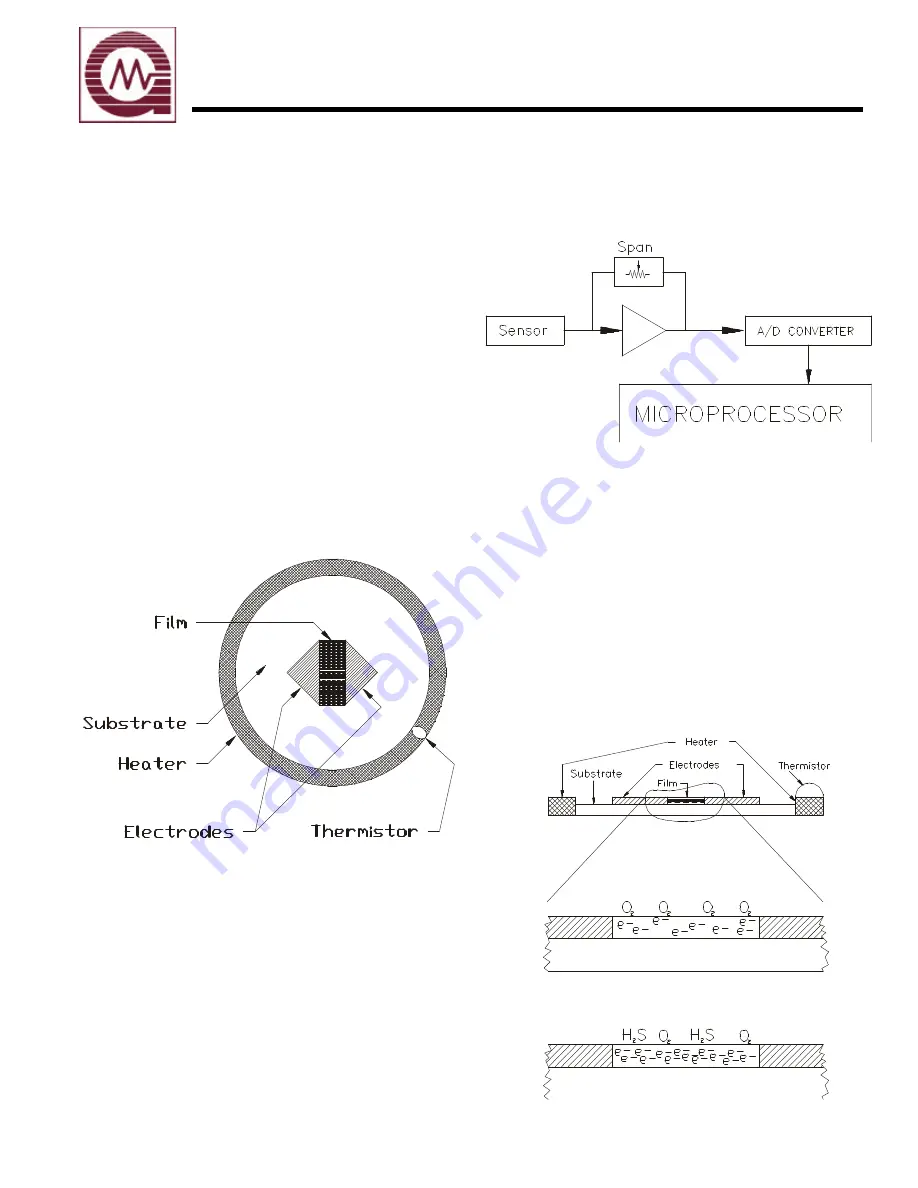

2.0 Sen sor As sem bly

2.1 Sen sor Sig nal Proc ess ing

General Monitors uses a proprietary Metal

Oxide Semiconductor (MOS) film on the

sensor for detecting hydrogen sulfide (H

2

S)

gas. The MOS film is deposited onto a

substrate between two electrodes (figure 1).

With no gas present, the measured resistance

between these two electrodes is very high (in

the mega-ohms). As H

2

S adsorbs onto the

film, the resistance between the two

electrodes decreases (to kilo-ohms). This

decrease in resistance is logarithmically

proportional to the concentration of H

2

S that

is present.

fig ure 1

The change in resistance is converted to a

change in voltage and amplified by the input

circuit (figure 2). This amplified signal is fed

to an Analog to Digital (A/D) Converter,

converted to a digital signal and sent to the

microprocessor to be processed. The process

of H

2

S adsorbing onto the MOS film is most

effective at an elevated temperature. On the

outer edge of the substrate is a heater ring.

fig ure 2

The temperature of this heater ring is

measured with a thermistor and kept constant

by a circuit located inside the body of the

sensor. As H

2

S adsorbs onto the film,

electrons move more freely from one

electrode to the other (figure 3). This is

represented as a decrease in resistance. The

process of H

2

S adsorbing onto the MOS film

is completely reversible. As the

concentration of H

2

S decreases (H

2

S

desorbs), the resistance between the

electrodes will increase.

fig ure 3

3

GENERAL MONITORS

Model S214