5

www.geiger.de

EN

EN

6. Installation instructions

I

Before fixing, the strength of the masonry or of the subsurface is to be

checked.

I

Prior to installation please check to ensure there is no visible damage

to the motor like cracks or open cables.

I

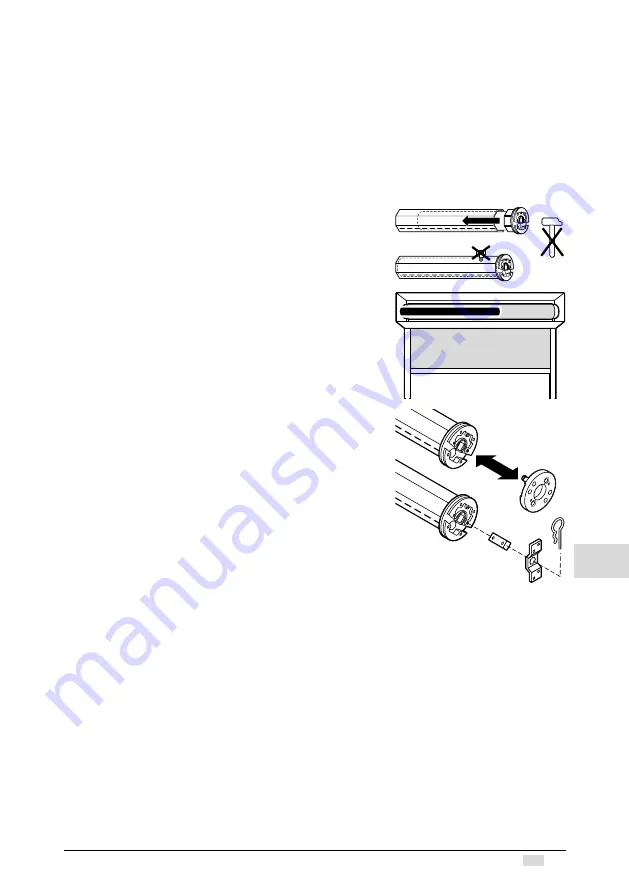

Caution: If the tube is screwed/riveted to the drive, the measure must

be taken from the tube end to the center of the drive and marked on

the tube.

When drilling the winding shaft

never

drill into the

area of the tubular motor!

When inserting into the shaft, the tubular motor must

not

be struck and must

not

be allowed to fall into the shaft.

Installation into the screen:

Insert motor with a suitable adapter and drive into the shaft

up to the stop of the shaft adapter.

Fix the motor support on the side piece.

Fix the motor together with the shaft on the motor support.

Depending on the selected motor head,

different fixation systems can be used:

– Place the motor with square insert in the star-shaped

bearer and lock with pin

– Place the motor into the existing engine bearer and

lock

– Place the motor in a compatible engine bearer with clip

system and lock with spring or rotating lever

I

The Geiger-SOLIDline motor is suitable

for shaft diameters from 50 mm!