Chapter 5: Repair Procedures

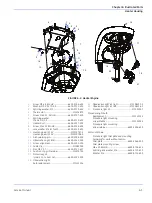

Lower Unit Repairs (Bedded and Freestanding Models)

5-24

Service Manual

5.7.5 Adjusting Bed Height Using Manual Elevating Column (Bedded Model Only)

Units without an electric elevating column (not equipped with foot switches) can be adjusted manually.

•

On older units, the adjustment system consists of a pin driven across the width of the column,

seven pairs of setting holes in the inner stationary column, and a gas spring inside the column to

compensate for the weight of the bed and heater while height is being adjusted.

•

On newer units, the adjustment system consists of a socket on the column and a separate crank

handle.

Manually adjustable units will be shipped at the lowest bed height setting.

5.7.5.1 Adjusting Bed Height on Units with the Pin

Increasing the bed height is relatively easy, since the spring force pushes the bed up. However, decreasing

bed height will require two people, unless a tool such as a ratchet strap is used to compress the spring and

lower the bed to the desired height.

1.

The adjustment pin is held in place by retaining screws (with large diameter flat heads counter bored in

the column) that fit into threaded holes in both ends of the pin. Use a large screwdriver to remove one

of these slot head retaining screws that are located on either side of the warmer, about half way up the

column. It does not matter which side of the column: either retaining screw can be removed. If the unit

is equipped with a suction canister bracket, you may wish to remove it.

2.

Using a rubber hammer or mallet and a large screwdriver or punch, drive the pin out from the end with

the retaining screw removed (you may wish to hold the bed down so that it does not jam the

screwdriver as the spring is released).

3.

Allow the bed to rise to the desired height. If possible, do not allow the bed to reach its highest point,

where the internal spring is fully extended, since this makes compressing the spring to lower the bed

more difficult.

Note:

The best way to compress the spring is to push down on the main bracket casting directly above the

column. However, this spot is not easily accessible. A strong board or piece of wood about a meter

long can be passed under the bed across the top of the casting, then both installers can press down

evenly on both ends of the board, until the column reaches the desired bed height.

4.

While one installer holds the bed in position, the other checks the alignment of the holes on one side of

the column, and then drives in the pin. It may be necessary to use a small screwdriver or hex key as a

lever to push up or down on the pin end inside the column to align the pin and the holes on opposite

side.

5.

Re-install the retaining screw to secure the pin and lock the bed in place.

Summary of Contents for PANDA

Page 4: ...RH 2 Service Manual...

Page 12: ...ii Service Manual About this Manual User Responsibility...

Page 38: ...Chapter 1 Functional Description System Functions 1 14 Service Manual FIGURE 1 8 Power Failure...

Page 60: ...Chapter 2 Installation Maintenance and Checkout Scale Checkout Procedures 2 8 Service Manual...

Page 62: ...Chapter 3 Calibration Scale Calibration Bedded Models Only 3 2 Service Manual...

Page 172: ...Chapter 6 Illustrated Parts Wiring Diagrams 6 40 Service Manual...

Page 180: ...Appendix A Specifications SpO2 Specifications A 8 Service Manual...