31-5000276 Rev. 1

11

Installation Instructions

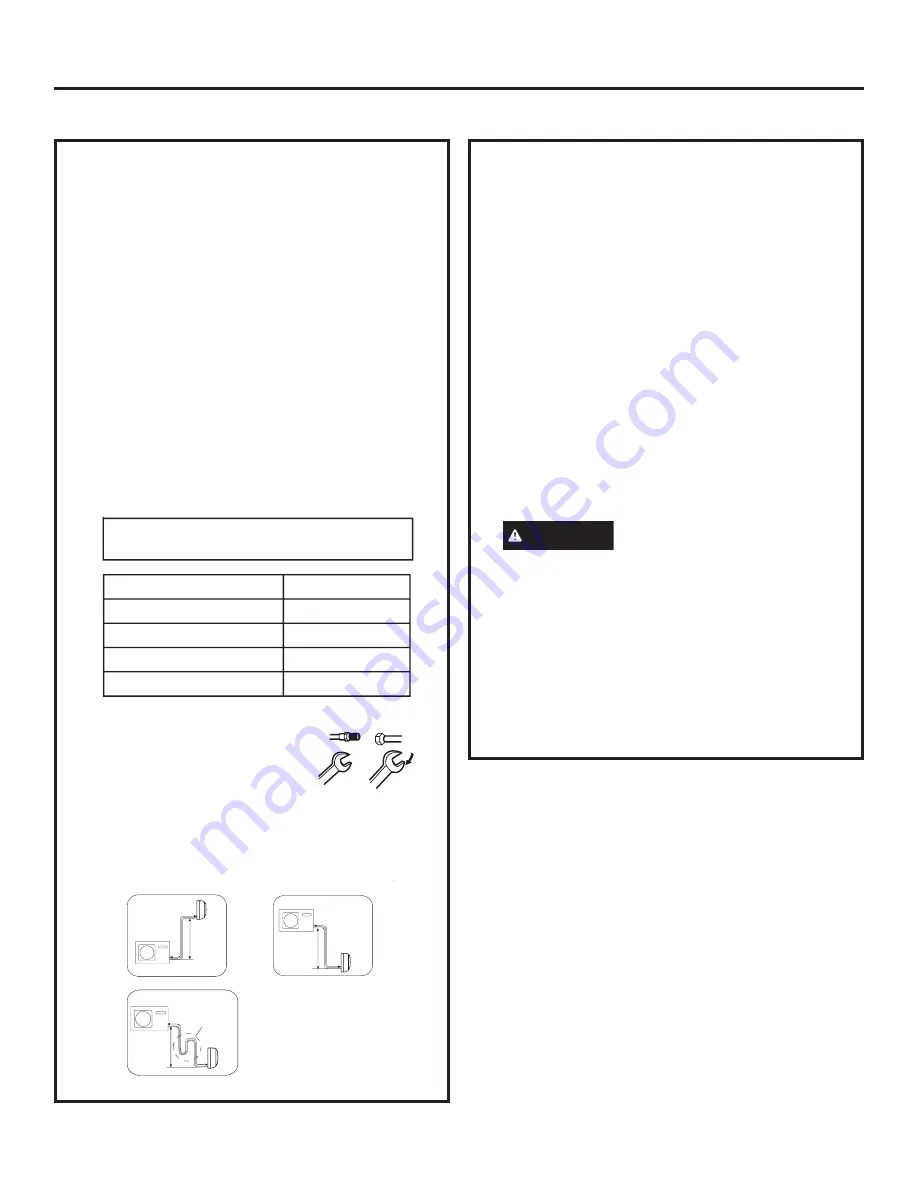

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

B

Outdoor unit

Indoor unit

Oil trap

CAUTION*

Max. Elevation: A Max

= 33ft / 10m (09k / 12k)

= 50ft / 15m (18k / 24k)

In case the height of A is more than

15ft / 5m, an oil trap should be

installed every 16-23ft /5-7m

Max. Length: B Max

= 50ft / 15m (09k / 12k)

= 83ft / 25m (18k / 24k)

●

●

●

*NOTE: Oil trap is only required for

218JRDWD*, other multi-split systems

don’t require oil trap.

Step 3 - Installation of the Outdoor Unit (Cont.)

C. Install Copper Lineset

• The standard line set length is 25 feet. If

the installation length is different, adjust the

refrigerant charge by adding 0.2 oz/ft if the liquid

line is 1/4”, or 0.5 oz/ft if the liquid line is 3/8”.

• See table on page 15.

• Cut the line set to length.

• Place nut over the pipe and then flare with the

R-410A flaring tool.

NOTE:

Follow standard practices for creating

pipe flares. When cutting and reaming the

tubing, use caution to prevent dirt or debris

from entering the tubing. Remember to place

nut over the tubing before flaring.

• To join the line set, directly align the tubing

flare to the fitting on the other pipe. Slide the

nut onto the fitting and hand tighten.

• Torque the fittings according to the

specifications shown in the torque chart below.

• Two wrenches are required

to join the flare connection;

one standard wrench and

one torque wrench adjusted

to the proper settings.

• Repeat the process for

attaching the other end of

the line set.

D. Leak Test

• Remove the cap on the service valve.

• Using a tank of dry nitrogen and approved

regulator, charge the system with 150 psig of

dry nitrogen using mini split adapter to connect

the valve.

• Check for leaks at the flare fittings using soap

bubbles or another detection device. If a leak

is detected, make repairs to the fittings and

recheck. If no leaks are detected within 3

minutes, proceed.

• Using the same tank/regulator, charge the

system to 300 psig.

• Check for leaks as earlier. If no leaks are

detected within 3 minutes, proceed.

• Using the same tank/regulator, charge the

system to 500 psig.

• Check for leaks as earlier. Keep system

pressurized for at least 20 minutes.

WARNING

Do not use acetylene, oxygen,

compressed air or any mixture containing

anything other than dry nitrogen. Use only dry

nitrogen for pressure testing. Do not use mixtures

of hydrogen containing refrigerant and air above

atmospheric pressure for pressure testing, as they

may become flammable and could result in an

explosion. Refrigerant, when used as a trace

gas, should only be mixed with dry nitrogen for

pressurizing units. Failure to follow these

recommendations could result in death or serious

injury as well as equipment or property damage.

Half union

Flare nut

Torque wrench

Spanner

Forced fastening without careful centering may

damage the threads and cause a refrigerant leak.

Pipe Diameter(

ǿ

)

Fastening torque

Liquid side 6.35mm(1/4") 18N.m/13.3Ft.lbs

Liquid/Gas side 9.52mm(3/8")

42 N.m/30.1Ft.lbs

Gas side 12.7mm(1/2")

55N.m/40.6Ft.lbs

Gas side 15.88mm(5/8")

60 N.m/44.3Ft.lbs

Half union

Flare nut

Torque wrench

Spanner

Forced fastening without careful centering may

damage the threads and cause a refrigerant leak.

Pipe Diameter(

ǿ

)

Fastening torque

Liquid side6.35mm(1/4")

18N.m/13.3Ft.lbs

Liquid/Gas side9.52mm(3/8") 42 N.m/30.1Ft.lbs

Gas side 12.7mm(1/2")

55N.m/40.6Ft.lbs

Gas side 15.88mm(5/8")

60 N.m/44.3Ft.lbs

Summary of Contents for ASH124CRDWA

Page 16: ...16 31 5000276 Rev 1 Printed in China...

Page 30: ...30 31 5000276 Rev 1 NOTES...