Novitool® AERO™ Portable Splice Press Welding Guidelines

PC10 and PC20

Novitool® AERO™ Portable Splice Press Welding Guidelines – V6

Page 5

2. Cut the belt.

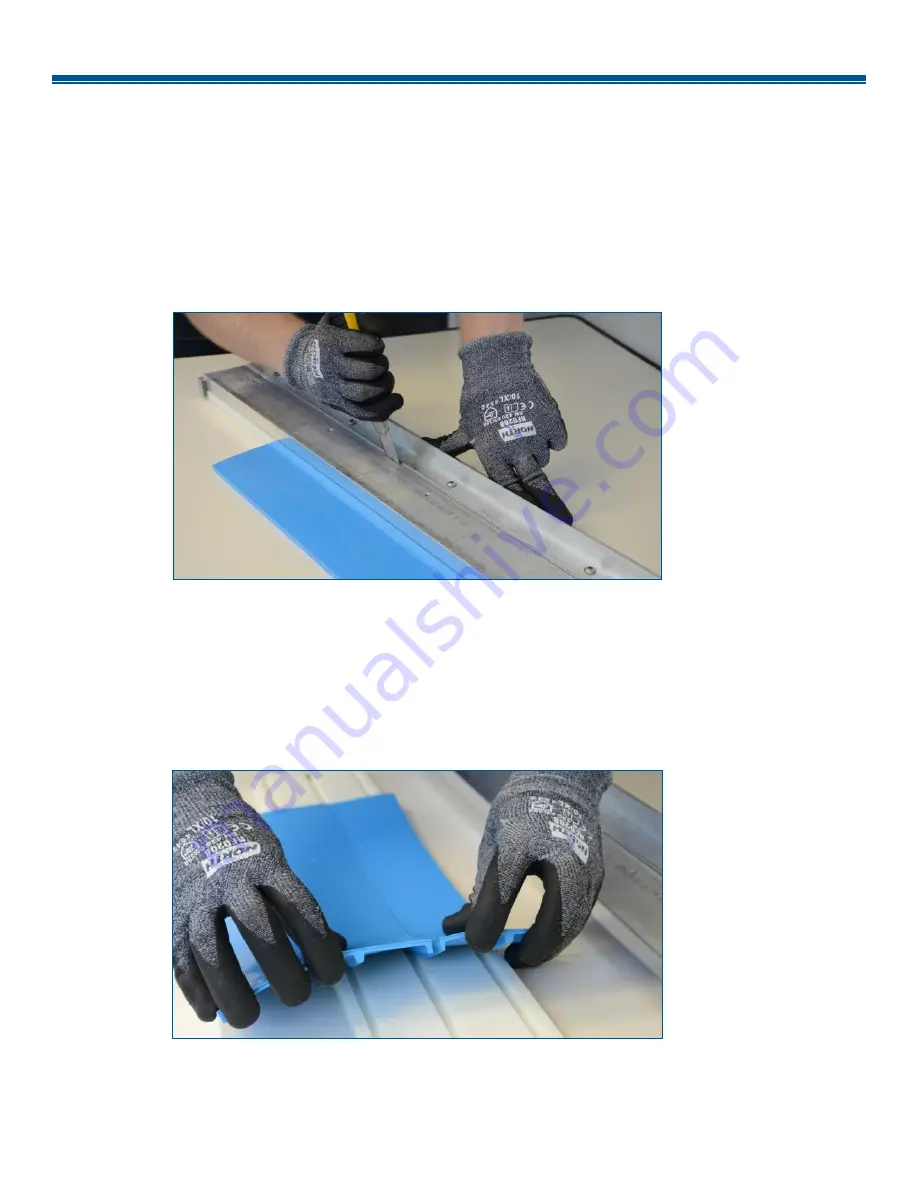

A. Insert one end of the belt into the cutting fixture.

(Must have ~ 3 teeth of extra material on the scrap side that will be cut off. This will keep the belt in

place while cutting.)

Ensure that the belt is fully engaged in the cutting guide groove.

B. Place top of the cutting fixture on the top of the belt, apply pressure on it with one hand.

C. Using your other hand, make several straight scoring cuts with the utility knife.

(Do NOT try to cut the belt in one deep cut. It does not work!)

D. You will have two split teeth. Ideally both cut halves would be equal to or slightly larger than half a

tooth. Slightly oversizing creates helpful side pressure when the two halves are forced into the silicone

pad. Welding two cut halves, that together make up less than a full tooth, will cause the belt to thin out

in the tooth area and could compromise the weld due to lack of side pressure pushing the two halves

together.

Straight Cut with Utility Knife

Two Split Teeth