Operation

Dimple Grinder User’s Guide

19

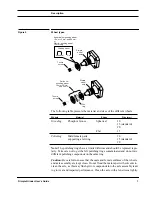

4.7 Polishing

When grinding has reduced the specimen thickness to within a few microns of

the final thickness, the grinding wheel is replaced with a felt polishing wheel.

Generally, a polishing treatment improves the final specimen quality obtainable

with subsequent ion milling.

To polish

1. Remove the grinding wheel and wipe the axle with a clean lens tissue.

If the contamination is difficult to remove, lightly moisten the tissue with

water or a solvent (e.g., acetone).

Caution: Do not flood the male taper with solvents to clean the axle as this may

flush grit or compounds into the axle assembly and lead to bearing wear and

impair performance.

2. Remove the specimen mount from the Turntable.

Thoroughly clean the specimen of all grinding compound. Use a cotton

swab and distilled water followed by flushing with acetone.

3. Carefully mount the polishing wheel onto the axle.

4. Place the specimen mount back onto the Turntable and center using the

microscope.

Precise centering is unnecessary for the final polishing step.

5. Set a higher rotational speed for polishing and set a load of about 30 g.

6. Apply a small quantity of 2–4 µm diamond paste to both the felt wheel

and specimen.

Note: Take care not to get the felt polishing rings contaminated and do not mix

different polishing compounds on the same ring.

7. Gently lower the polishing wheel onto the specimen.

Polish until the surface finish is improved (normally requires only a few

minutes).

8. Use a new felt wheel and repeat with 0.05-µm alumina.

Polish until the surface is free of scratches produced by the 2–4 µm diamond

paste.

Note: The softness of the felt polishing wheels makes the measuring system

inaccurate. From time to time, monitor the polishing progress with the stereo

Summary of Contents for 656

Page 2: ...Part Number 656 82002...

Page 6: ...iv Dimple Grinder User s Guide...

Page 10: ...viii Dimple Grinder User s Guide...

Page 42: ...Spares and Consumables 32 Dimple Grinder User s Guide...

Page 44: ...I 2 Dimple Grinder User s Guide...

Page 48: ......