Description

6

Dimple Grinder User’s Guide

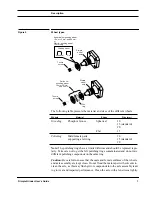

Figure 4

Wheel position alignment.

Grinding Wheels

The grinding wheels are phosphor bronze, available with spherical or flat edges.

The spherical-edged wheel permits more accurate positioning of dimples and

produces a spherical profile with a smaller thin area. This wheel is more suited

to fragile or brittle specimens, such as ceramics and semiconductors.

The flat-edged wheel produces flat bottomed dimples with larger thin regions

and is better suited to tougher specimens, particularly metals.

Wheels come in different sizes. The small wheel preserves a wide, thick rim

around the thin area for fragile specimens and produces steep profiles for analy-

sis. The large wheel prepares bulk specimens for larger thin areas. All wheels

are interchangeable.

Note:

The grinding wheels wear and are considered consumable items.

Polishing Wheels

The polishing wheel consists of male and female parts that hold a central felt

polishing ring (see Figure 5).

Standard

grinding wheel

contact point

Specimen

Specimen

rotation

axis

Pivot point

of rotating

grinding arm

Large

grinding wheel

contact point

Standard

grinding

wheel

Large

grinding

wheel

β

Specimen

mount

Summary of Contents for 656

Page 2: ...Part Number 656 82002...

Page 6: ...iv Dimple Grinder User s Guide...

Page 10: ...viii Dimple Grinder User s Guide...

Page 42: ...Spares and Consumables 32 Dimple Grinder User s Guide...

Page 44: ...I 2 Dimple Grinder User s Guide...

Page 48: ......