Operation

Dimple Grinder User’s Guide

11

•

Set grinding by final specimen thickness.

Both methods are based on the interaction of the Micrometer Drive and the ana-

log Dial Indicator.

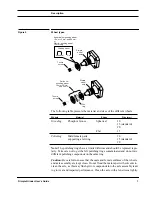

The Dimple Depth digital display shows the desired dimple depth set by lower-

ing the end face of the Micrometer Drive.

The analog Dial Indicator shows the progress of grinding and displays the thick-

ness of specimen material remaining to be removed.

When the Dial Indicator stylus makes contact with the micrometer end face,

grinding is terminated by the AutoTerminator, which will automatically switch

off the wheel and specimen turntable motors (see Figure 8).

The rate of removal of material by grinding depends on several factors. Gener-

ally, increasing the load and/or grinding wheel speed will increase the rate of

material removal. However, this will also produce a thicker damaged layer. It

should also be noted that some hard metals work harden significantly and these

are best dimpled at a slow speed with reduced load.

Grinding by Dimple Depth

This method is used when very thin (<20µm) specimens are being dimpled.

The Micrometer is first zeroed on the upper surface of the specimen and the

desired dimple depth is set with the Micrometer Drive and value read on the

digital display.

The initial thickness of the specimen must be known

.

This method is the most accurate way to grind specimens but it is necessary to

zero the Micrometer for each specimen.

See Section 4.5 for more detailed instruction on this method.

Grinding by Final Specimen Thickness

This method is less accurate than the “dimple depth” method and is not recom-

mended for very thin specimens.

The Micrometer is first zeroed on the upper surface of a specimen mount

with-

out any specimen

. The mount is replaced with a mount with a specimen and the

desired amount of material to be removed is dialed in using the Micrometer

Drive.

The advantages of this method are the initial thickness of the specimen need not

be ascertained and the Micrometer is zeroed only once when dimpling a number

of specimens.

Summary of Contents for 656

Page 2: ...Part Number 656 82002...

Page 6: ...iv Dimple Grinder User s Guide...

Page 10: ...viii Dimple Grinder User s Guide...

Page 42: ...Spares and Consumables 32 Dimple Grinder User s Guide...

Page 44: ...I 2 Dimple Grinder User s Guide...

Page 48: ......