USE AND MAINTENANCE

68

ENGLISH

g

cod. G19502113

4.0 OPERATIONS FOR PUTTING THE MACHINE

INTO SERVICE

4.1 WHEN THE MACHINE IS NEW

- Assemble onto the equipment any parts that may have been delivered

disassembled for transport purposes (follow the instructions given

in the assembly diagrams attached to these parts).

4.2 CHECKS AND PREVENTATIVE MAINTENANCE

- Check that the safety bolts are present on the pins:

a)

3-point linkage connecting pins;

b)

pins for locking the row marker arms for road transport.

- Check that the pipes of the hydraulic system are undamaged.

- Check that all the screws are tight.

- Grease the universal joint spiders.

- Grease the row-marker disc pin.

- Check that all the suction tubes are well connected.

- Check that all the drive shafts are properly engaged.

- Carefully check moving parts, dri-ving parts and seed

distribution.

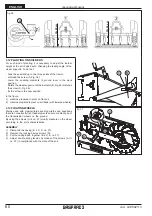

4.3 ATTACHMENT THE TRACTOR

- Connect the equipment to the third point of the tractor using the

safety devices.

- Connect the cardan shaft.

- Connect the hydraulic pipes to the distributors of the tractor.

- Plug the visual signalling units into the socket of the tractor's

electrical system.

- Remove the safety bolts of the row marker arms and the toolbar,

and operate the hydraulic systems to check they are working

correctly. If necessary, adjust the flow regulators where present.

- Lift the equipment off the ground and remove the support legs.

- When travelling by road, lock the row marker arms and the toolbar

in transport position with the safety bolts.

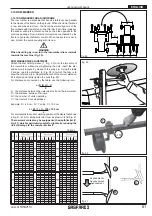

4.4 PREPARING FOR SEEDING

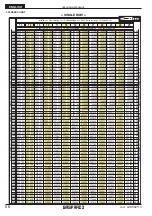

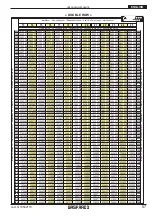

- From the seed chart, according to the row spacing, obtain the

distance between one seed and the next along the row.

- From the longitudinal sowing distance adjustment table, obtain

the combinations of gears on the gearbox and on the drive

wheel that will produce this distance.

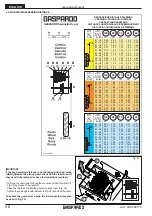

- Insert the right seed discs in the distributors.

- Put a small quantity of seed in the hoppers.

- From the driverís seat of the tractor, raise the seeder;

- Operate the power take-off;

- Using the gear lever, put the tractor engine into neutral;

- Brake the tractor and if necessary, secure it with wooden blocks

sized according to the size of the wheels;

- Manually turn the seeder gear drive wheel in the direction in

which the machine is moving;

- Adjust the selector and control through the grate that the plate is

only holding one seed per hole;

- Adjust the planting depth.

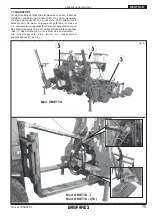

- Check the degree of preparation of the seedbed and adjust the

height of the front clod clearer.

- Move along the seedbed for a few metres with the equipment in

working position, and adjust the third point tie rod to obtain true

perpendicularity between machine and ground.

- Start sowing: after a few metres check whether the distributors

are correctly dropping one seed at a time.

4.5 DISTRIBUTION OF CHEMICAL PRODUCTS

- Hoppers and tanks can be filled by hand or using a lifter with a

capacity of at least 200 kg, which must be regularly approved by

the relative authorities.

- When filling the fertilizer and insecticide hoppers, be careful

that foreign bodies do not enter (string, bag paper, etc.).

- Set the quantity to distribute following the information given in

the table (the values given in the table are a rough guide only).

- Adjust the working depth and the distance of the fertilizer

placement units from the sowing row, carefully following the

specific agronomic instructions of each crop.

4.6 DURING SEEDING

- At the end of each run, while reversing, always keep the power

take-off running at sufficient revs. per minute to ensure that the

seeds remain attached to the distributor plates.

- During seeding check the seed distribution frequently and, if

irregular, adjust the selector.

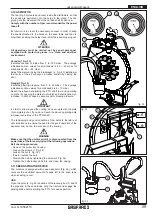

- If there is a loss or decrease of suction, check that the pipes

are not damaged or clogged; if so, replace or clean them,

checking the aspirator belt also.

CAUTION

- The shape, dimensions and material of the drive shaft elastic

pins have been selected for reasons of safety. The use of

non-original or more resistant pins could cause serious dam-

age to the seeding machine.

- Start the power take-off gradually; sudden movements are

harmful to the aspirator belt.

- Avoid curves with the machine grounded, and do not work in

reverse. Always lift it when changing direction or reversing.

- Do not work with the power take-off synchronized with the

wheels.

- Do not exeed the number of revolutions per minute indicated

on the power take-off.

- Never push the tractor to maximum revs.

- Maintain a seed planting speed that is compatible with the

type and preparation of the soil in order to avoid breakages

or damage.

- Low the seeding machine while the tractor is moving so as

not to clog or damage the coulter parts. For the same reason

it is unadvisable to manoeuvre in reverse with the seeder

lowered.

- When filling the seed, fertilizer and insecticide hoppers,

ensure that no foreign bodies (string, paper, etc.) enter them.

DANGER

The seeding machine can transport chemical substances. Do

not allow children, people, pets to come near the seeding

machine.

WARNING

Do not place any bags of fertilizer or any other object on the

fertilizer distributor container covers to avoid breaking them

or endangering property or persons. Load from the outer sides

of the machine.

It is forbidden to come near the containers of the chemical

substances or to open them when the seeding machine is

operating or about to operate.

Summary of Contents for ORIETTA

Page 4: ...cod G19502113 g 4...

Page 37: ...37 g Notes cod G19502113...

Page 38: ...cod G19502113 g 38...

Page 71: ...71 g Notes cod G19502113...

Page 72: ...cod G19502113 g 72...

Page 105: ...105 g Notes cod G19502113...

Page 106: ...cod G19502113 g 106...

Page 139: ...139 g Notes cod G19502113...

Page 140: ...cod G19502113 g 140...

Page 173: ...173 g Notes cod G19502113...

Page 174: ...cod G19502113 g 174...