Operating The Air Seeder

Page

31

05/06

While the blower is warming up

check

that the meter shafts turn freely.

Refer to

the “Metering System’ for further details.

IMPORTANT

On

cold

wet

mornings

it

is

recommended that you run the blower at its

operating speed for at least 10 to 15

minutes before seeding. This extended

start-up time will help dry the distribution

system if moisture is present.

It is suggested that the operator does

not lower the points of the implement into

the ground until the machine is moving.

This will help in preventing the sowing

boots

becoming

blocked

in

muddy

conditions.

Engage the clutch on Ground Drive

Models or take monitor off hold on VRT

Seeders when you wish to apply material.

To stop seeding, simply turn the clutch off

or place monitor on hold on VRT Seeders.

This will disengage the drive system.

Monitor Operation

The monitor system is different for the

Ground Drive and VRT equipped seeders.

The operator should read the specific

monitor manuals supplied for all technical

information on installing and operating the

many features of each unit.

Before the monitor can be used the

appropriate sowing width needs to be

loaded, and for VRT seeders, a calibration

procedure performed.

To obtain basic information and the

preset values used on your specific model

supplied, refer to either the Ground Drive-

Monitor Operation section (page 32) or the

VRT Hydraulic Drive section (page 64).

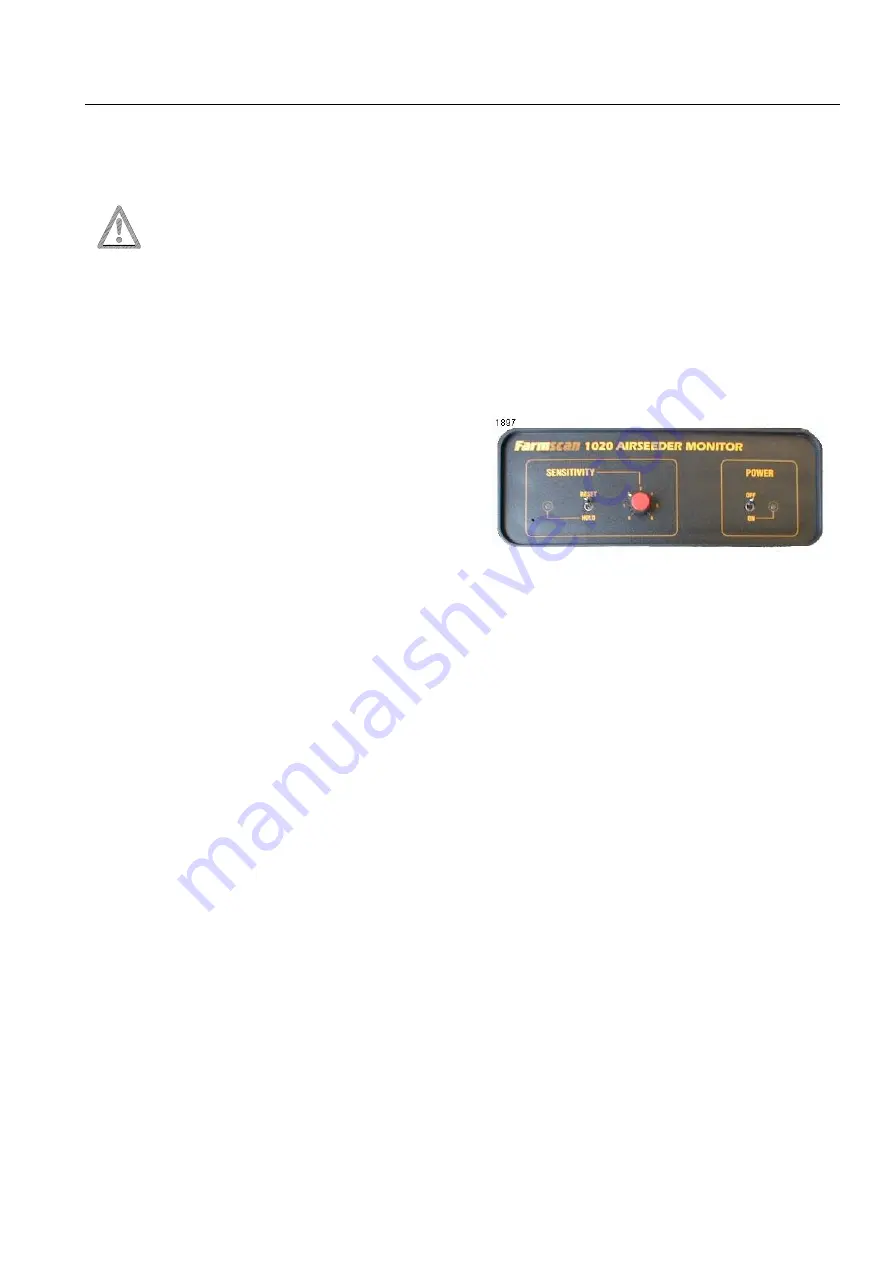

1020 Air Seeder Monitor

The main function of this monitor is to

show the operator that material is being

conveyed through the system to the

secondary head and warn against a

blockage in that secondary distribution

hose.

The monitor should be switched on

before operating the seeder. The toggle

switch on the front face of the monitor

should remain on “RESET”

Fig. O2 Farmscan 1020 Monitor.

Head Blockage Kit

The Gason Air Seeder is supplied with

one head blockage sensor (GPN 208651)

and harness. This can be expanded to 21

sensors at a later stage if necessary.

To operate, adjust the sensitivity

knob while conveying product so that the

monitors red light and audible warning

stops. If the red light comes on, check for a

blockage.

When finely adjusted the light will

sometimes flicker when the tractor slows or

turns. This is caused by either the material

rate dropping off because the drive wheel

on the seeder has slowed or fan speed has

reduced because of other demands on

hydraulic oil flow i.e. steering/implement lift.

The sensitivity of the monitor is such

that the system will pick-up this small

difference in the material rate or velocity.