Document # G_GHD_OM_PASTACUISINE_4607873 – 08/21

15

PREVENTIVE MAINTENANCE Continued

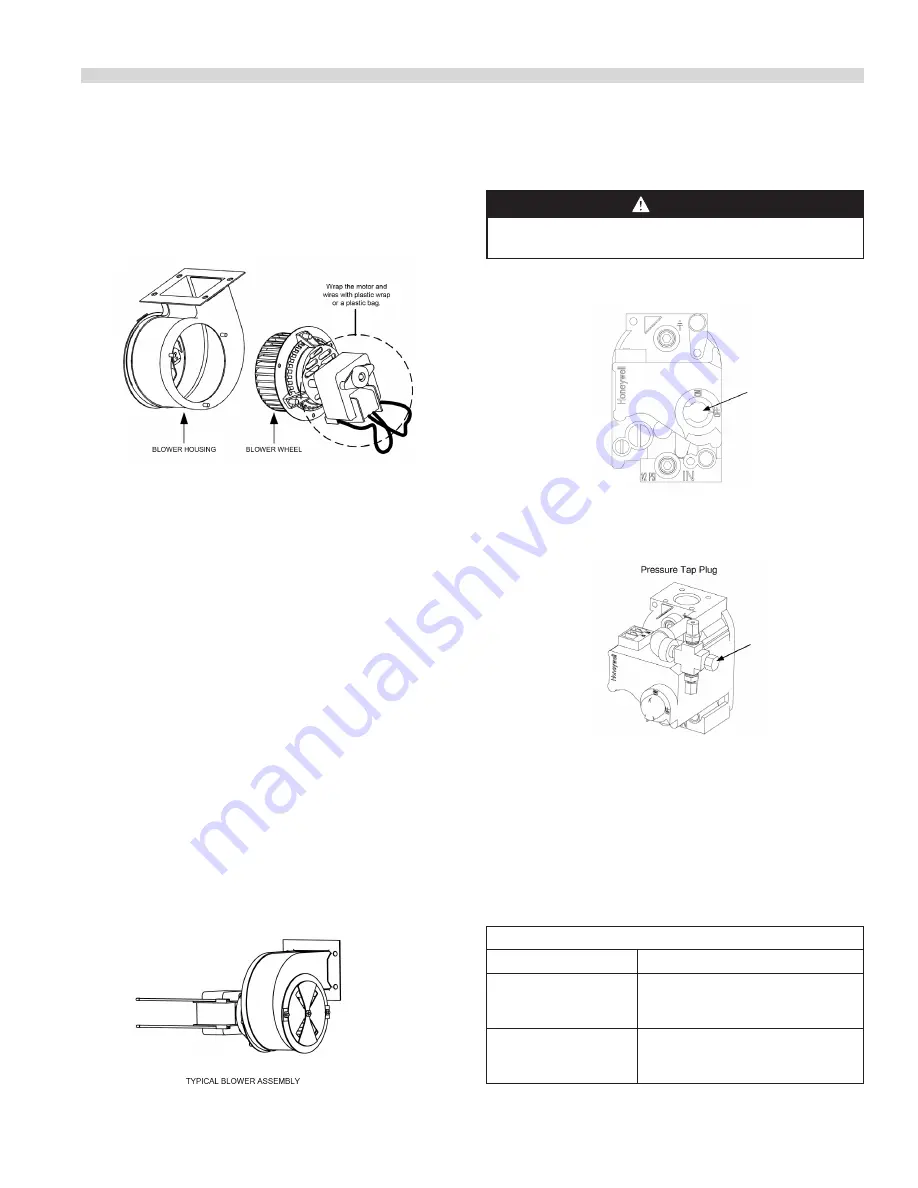

4. Wrap the motor with plastic wrap to prevent water from

entering it. Spray degreaser or detergent on the blower

wheel and the blower housing. Allow it to soak for five

minutes. Rinse the wheel and housing with hot tap

water, then dry with a clean cloth.

5. Remove the plastic wrap from the blower motor

assembly. Reassemble the blower motor assembly and

blower housing. Reinstall the blower assembly in the

cooker and reconnect the wires disconnected in Step 1.

4. Reinstall the blower shield or shield assembly.

5. Light the cooker in accordance with the procedure

described in section - Operating Instructions.

6. After the burners have been lit for at least 90 seconds,

observe the flames through the burner view-ing ports.

The air/gas mixture is properly adjusted when the burner

manifold pressure is in accordance with the applicable

table (Burner Gas Pressure- on this page) and the burners

display a bright orange-red glow. If a blue flame is

observed, or if there are dark spots on a burner face, the

air/gas mixture requires ad-justment.

On the side of the blower housing opposite the motor is

a plate with one or two locking nuts. Loosen the nut(s)

enough to allow the plate to be moved, then adjust the

position of the plate to open or close the air intake opening

until a bright orange-red glow is obtained. Carefully hold the

plate in position and tighten the locking nut(s).

Adjusting the Burner Gas Pressure

DANGER

Garland recommends that ONLY qualified service

personnel perform this task.

1. Ensure that the gas valve knob is in the

OFF

position.

2. Remove the pressure tap plug from the gas valve

assembly.

3. Insert the fitting for a gas pressure-measuring device into

the pressure tap hole

4. Place the gas valve in the

ON

position.

5. Place the power switch in the

ON

position. When the

burner has lit and burned steadily for at least one minute,

compare the gas pressure reading to the pressure for the

corresponding gas in the appropriate table below.

Burner Gas Pressure

Gas

Pressure

Natural

3” WC

.087 kPa

8.718 mbar

Propane

8.25” WC

2.05 kPa

20.55 mbar

Summary of Contents for PASTA MAGIC

Page 17: ...Document G_GHD_OM_PASTACUISINE_4607873 08 21 17 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 21: ...Document G_GHD_OM_PASTACUISINE_4607873 08 21 21 Notes...

Page 22: ...Document G_GHD_OM_PASTACUISINE_4607873 08 21 22 Notes...

Page 23: ...Document G_GHD_OM_PASTACUISINE_4607873 08 21 23 THIS PAGE INTENTIONALLY LEFT BLANK...