7

Version 1, 15 June 2020, 7 of 16

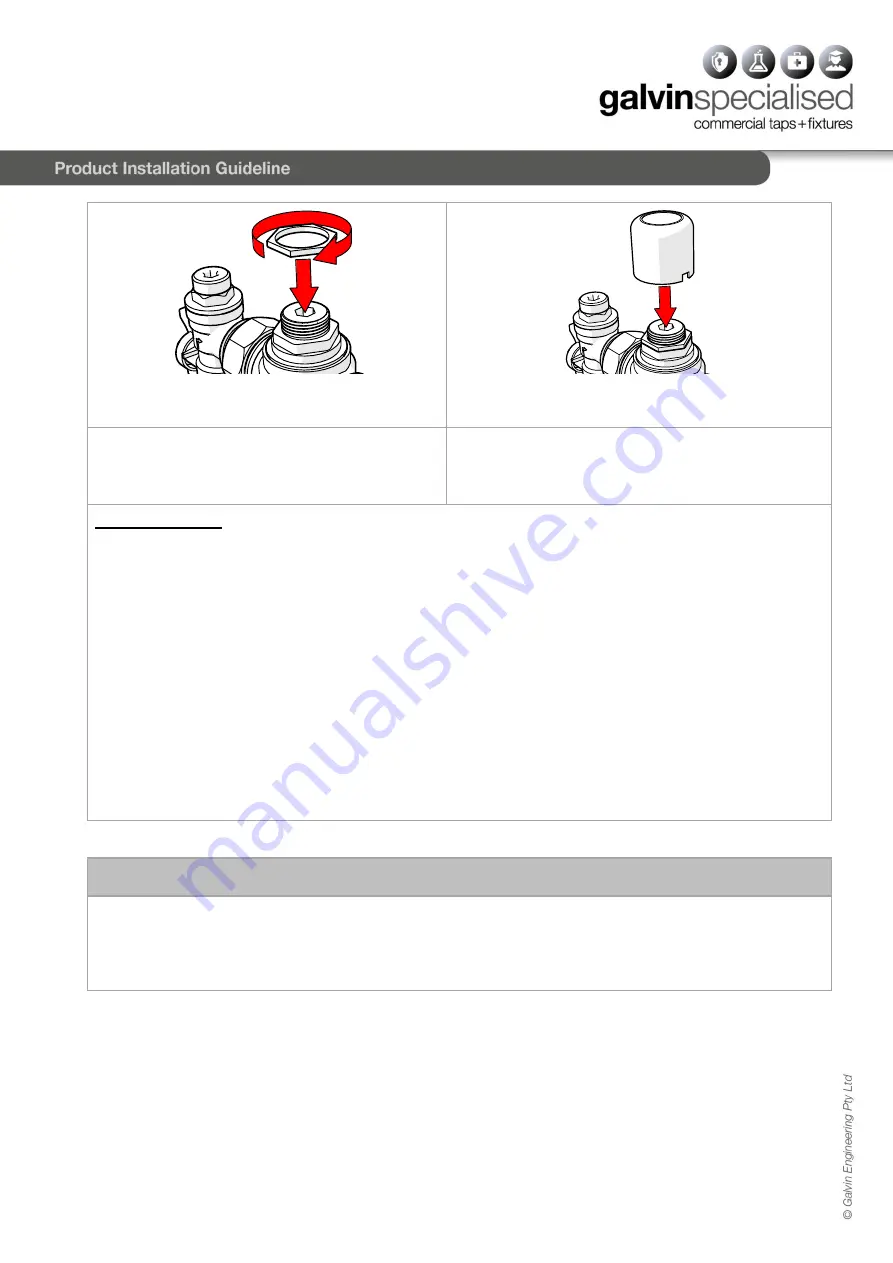

5. Retighten the Temperature Locking Nut with and

adjustable spanner

6. Push the top cover firmly on to the top of the valve until

is ‘snaps’ back into place.

7. Check the outlet temperature is stable over a full

range of flow rates and that the flow rate is

adequate for the application.

8. Close the outlet. The TMV is now set and locked.

SHUT DOWN TEST

Now that the TMV has been set and locked it is necessary to perform a shutdown check. Allow the mixed water

temperature to stabilize and note the outlet temperature. While holding a digital thermometer in the outlet flow,

quickly isolate the cold water supply to the valve. The outlet flow should quickly cease flowing. As a rule of thumb

the flow should be less than 0.1L/min following the isolation. Monitor the maximum outlet flow temperature, and

record this on the Commissioning Report (Appendix A). The temperature should not exceed that allowed by the

applicable standard or code of practice for each state and territory. Restore the cold water to the TMV. After the

mixed water temperature has stabilized note the outlet temperature ensuring the outlet temperature has

reestablished.

Now repeat the above test, except this time quickly isolate the hot water supply to the valve. The outlet should

quickly slow to a trickle. As a rule of thumb, the trickle should typically be less than 0.4L/min @ 500kPa down to

less than 0.1L/min @ 100kPa following the isolation. Restore the hot water supply to the valve and measure and

record the outlet temperature has stabilized ensuring the outlet temperature has reestablished.

Ensure that all details of the Commissioning Report are completed and signed by the relevant signatories. A copy

of this report should be kept with the installer and owner of the premises.

The valve is now commissioned and it can be used within the technical limits of operation.

8.0

MAINTENANCE AND SERVICING

The Galvin Engineering CliniMix

®

Thermostatic Mixing Valve will only require minimal preventative maintenance

work to ensure it operates at its optimum level of performance. The valve should be commissioned and serviced

annually, unless the installed conditions dictate more frequent servicing is necessary.