6

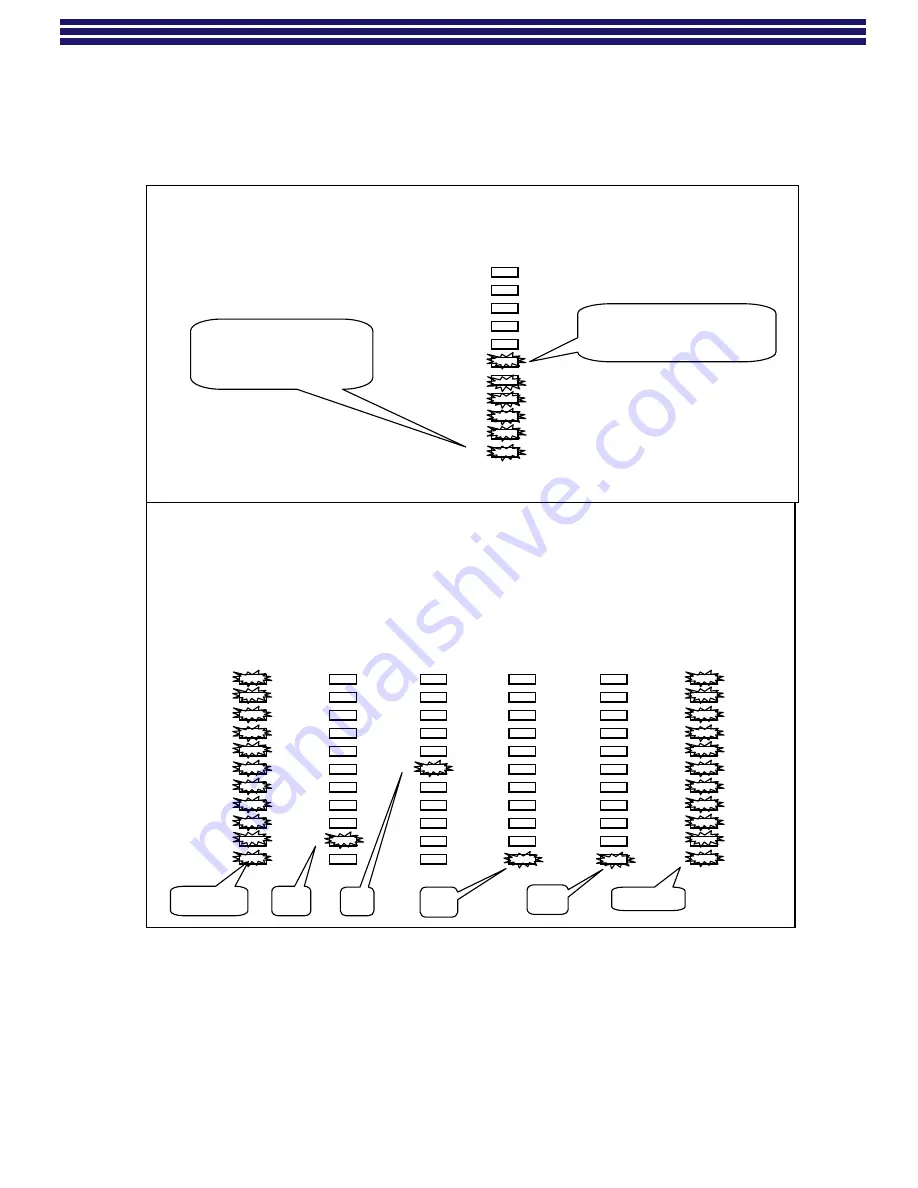

Bar Graph Display

&

Flash Codes

Code Flash Mode

All IGC values that are flashed out are always 4 digits. The LED’s are labeled as 0, 1, 2,..,10. Code

Flash mode can display any value between 0 and 9999. They would be displayed by flashing 0-0-0-0 thru

9-9-9-9 respectively. Please review the example below of displaying the value 1500.

1

5

0

0

repeat

repeat

Bar Graph Display

The Bar Graph displays the “approximate” percentage from 0 to 100%. Pressing the +/- arrow buttons,

increases or decreases the value. You may have to press the +/- button several times to illuminate the next

LED. This is due to the difference in resolution between the LED’s and the actual parameter being

adjusted.

EXAMPLE 1 –

Bar Graph displaying between 50% and 59%.

EXAMPLE 2 –

Code Flash mode displaying the number 1500.

If only LED 0 is on, the

value is between 0%

and 9%.

This indicates the value is

between 50% and 59%.

0

2

1

5

4

6

8

7

9

10

0

2

1

5

4

6

8

7

9

10

0

2

1

5

4

6

8

7

9

10

0

2

1

5

4

6

8

7

9

10

0

2

1

5

4

6

8

7

9

10

0

2

1

5

4

6

8

7

9

10

0

2

1

5

4

6

8

7

9

10

3

3

3

3

3

3

3

Summary of Contents for IGC700 Series

Page 2: ...2 Diagram 1...