4-6

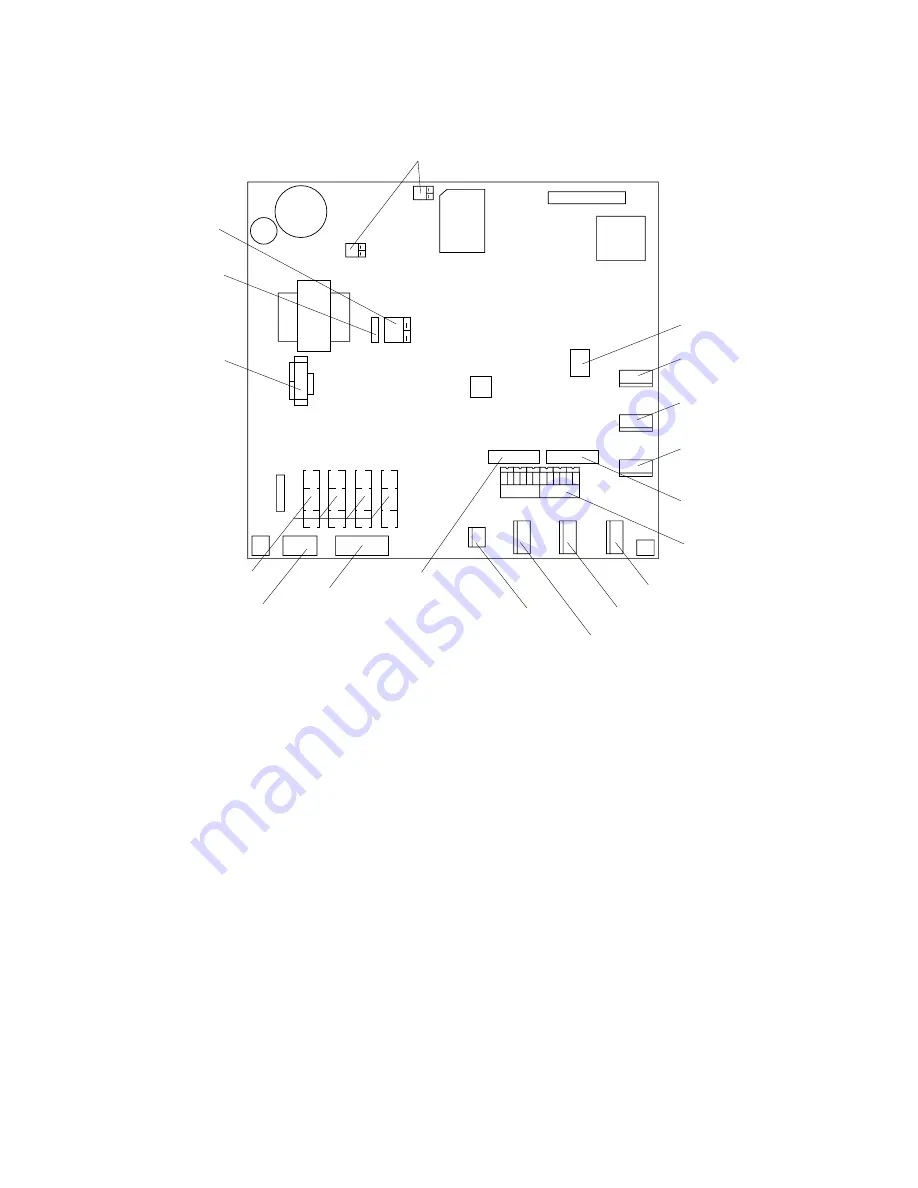

Location of DIP switches, jumper wires on the GYRO CONVERTER

Board

64P1106

JP5, JP4

(Supply voltage)

JP2

(Rotor voltage)

JP3

(Stator voltage)

JP1

(Gyro type)

Fuse

(2A)

J5

(Rotor signal input,

external power input)

J4

(Stator signal input)

SW1

DIP switch

J6

(IEC-61162-1 output port)

J7

(Data output port #1)

J8

(Data output port #2)

J9

(Data output port #3)

JP6, JP7

(AD formal

data Tx interval)

SW2

DIP switch

J10

(Data output

port #4)

J11

(Data output

port #5)

J12

(Data output

port #6)

SW3

DIP switch

Figure 4-4 GYRO CONVERTER Board

Setting the heading readout on the radar display

Confirm that the gyrocompass is giving a reliable readout. Then, set the heading

readout on the radar display with the gyrocompass readout as follows:

1. Press [RADAR MENU] to display the FUNCTIONS 1 menu.

2. Press the [0] key twice to display the FUNCTIONS 3 menu.

3. Press the [9] key to select the GYRO SETTING option.

4. Rotate the EBL control to align the radar’s HDG readout with the gyrocompass.

5. Press [ENTER] to conclude the setting.

Summary of Contents for FR-2135S

Page 1: ......

Page 24: ...This page is intentionally left blank ...

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......