User’s Manual for FD430 Digital 2-Phase Stepper Driver

User’s Manual for FD430 Digital 2-Phase Stepper Driver

15 16

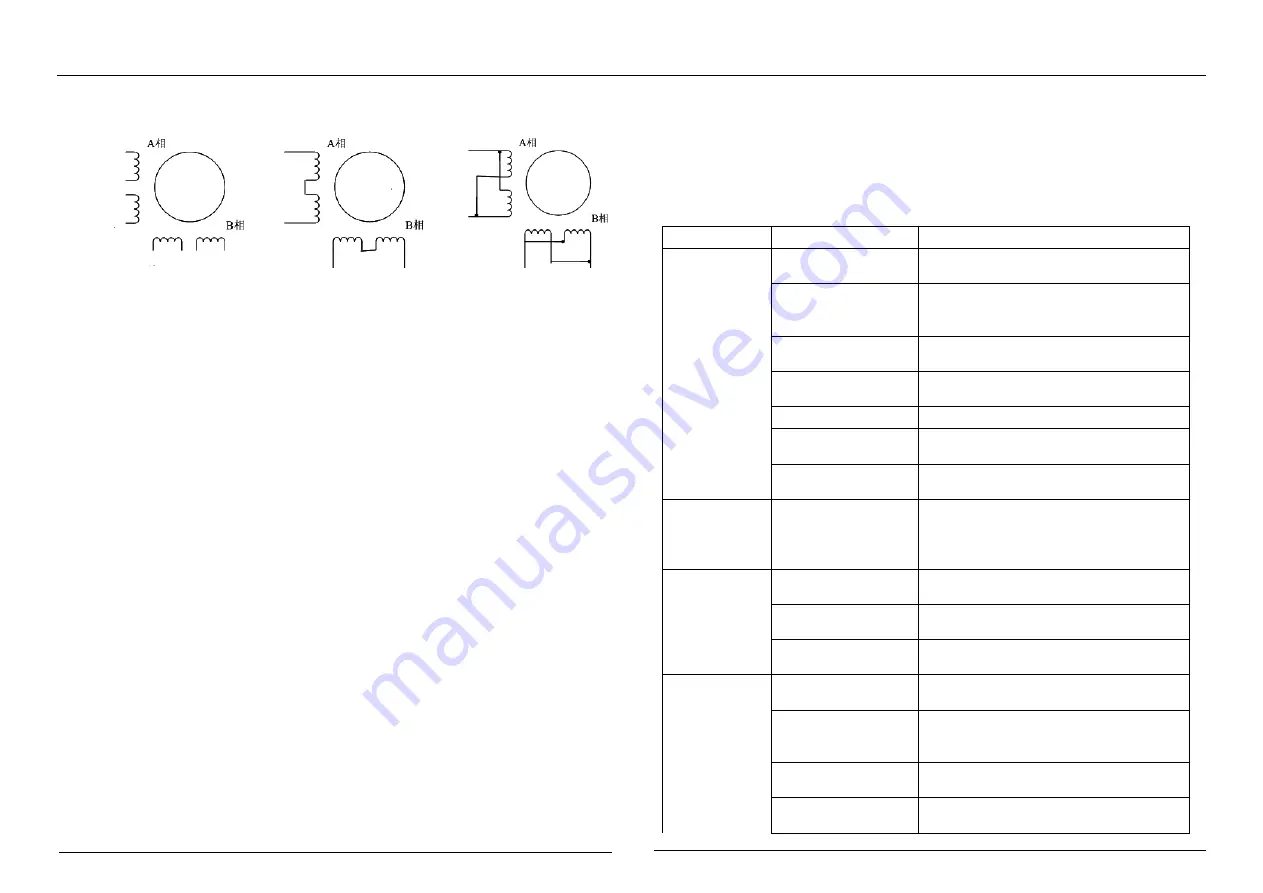

terminals of the same phase of the driver(A+,A- is one phase, B+,B- is another

phase). 57HS22 motor lead definition, Series and Parallel Connections method is

shown below.

3

)

FD430 driver can only drive 2-phase hybrid step motors, which cannot drive 3-phase

and 5-phase stepping motor.

4

)

The method of judging whether the stepping motor is connected in series or in

parallel is correct, When the driver is not connected, directly rotate the motor shaft

by hand, If it can rotate easily and evenly, then the wiring method is correct; If the

resistance is large and uneven rotation with a certain sound, then the wiring method

is incorrect.

Ⅷ

. Protection Functions

1

)

Short Circuit Protection / Over-current Protection

Over-current protection will be activated when continuous current exceeds the limit

current value or in case of short circuit between motor coils or between motor coil and

ground, and RED LED will turn on once within each periodic time (3 s). Reset the driver

by repowering it to make it function properly after removing above problems.

2

)

Over-voltage protection

When power supply voltage exceeds 38VDC, protection will be activated and RED

LED will turn on twice within each periodic time (3 s). Reset the driver by repowering it

to make it function properly after removing above problems.

3

)

Phase Error Protection

。

Motor power lines wrong & not connected will activate this protection. RED LED

will turn on four times within each periodic time (3 s). Reset the driver by repowering it

to make it function properly after removing above problems.

Attention

:

since there is no protection against power leads (

﹢

,

﹣

) reversal, it is critical

to make sure that power supply leads correctly connected to driver. Otherwise, the driver

will be damaged instantly.

Ⅸ

. Frequently Asked Questions

1. Problem Symptoms and Possible Causes

Symptoms

Possible Problems

Solution

Motor is not

rotating

No Power

Check the power supply circuit for normal

power supply

The motor shaft

strong, Control signal

is too weak.

Control pulse signal is too weak, Signal

current increased to 7~16mA

microstep resolution

is too small

select the right microstep resolution

setting

Current setting is too

small

Select the right current setting

Drive is protected.

Power on again

Enable signal is low

high.

Enable signal is high or not connected.

Does not respond to

Input control signals

Not powered.

Motor

rotating in the

wrong

direction

Motor phases may be

connected in reverse

Exchanging the connection of two wires

for a coil to the driver will reverse motion

direction.

Alarm

indicator is on

Wrong motor

connection

Check connection

Power supply is too

high or too low.

Check Power Supply

Motor or Driver is

bad

.

Replace motor or driver

Inaccurate

location

Control signal is

disturbed

Eliminate interference

Shielded ground is

not connected or

disconnect

Reliable grounding.

Open winding of

motor

Check motor wire

Micro-step resolution

setting is wrong.

select the right micro-step resolution

setting

Lead definition

Tandem

Parallel

57HS22

57HS22

57HS22

蓝

S45

红

S45

黄

S45

绿

S45

白

S45

橙

S45

棕

S45

黑

S45

Figure8 Tandem and Parallel connection