User’s Manual for FD430 Digital 2-Phase Stepper Driver

User’s Manual for FD430 Digital 2-Phase Stepper Driver

7 8

3

RxD

RS232 receive

4

GND

Ground

0V

5

NC

Notice: The FD430 RS232 cable must be a special cable, which is provided according to

the user’s situation, Please confirm the cable before use to avoid damage.

4

)

LED Status Indicator

The green LED is Power indicator light, The LED turns on when the driver is powered on

and functions normally. When driver is powered off, the LED is off. The FD542 uses one

RED LED to indicate what protection has been activated. The red LED blinks

periodically (in every 3 seconds) to indicate the error type. When the fault is cleared by

the user, the red LED is always off. The specific relationship is shown in the following

table.

Number

Time(s) of

Blink

Sequence wave of Red LED

Description

1

1

Over current protection

or Single short circuit

between two phases

2

2

Over Voltage protection

3

3

No definition

4

4

No definition

2.

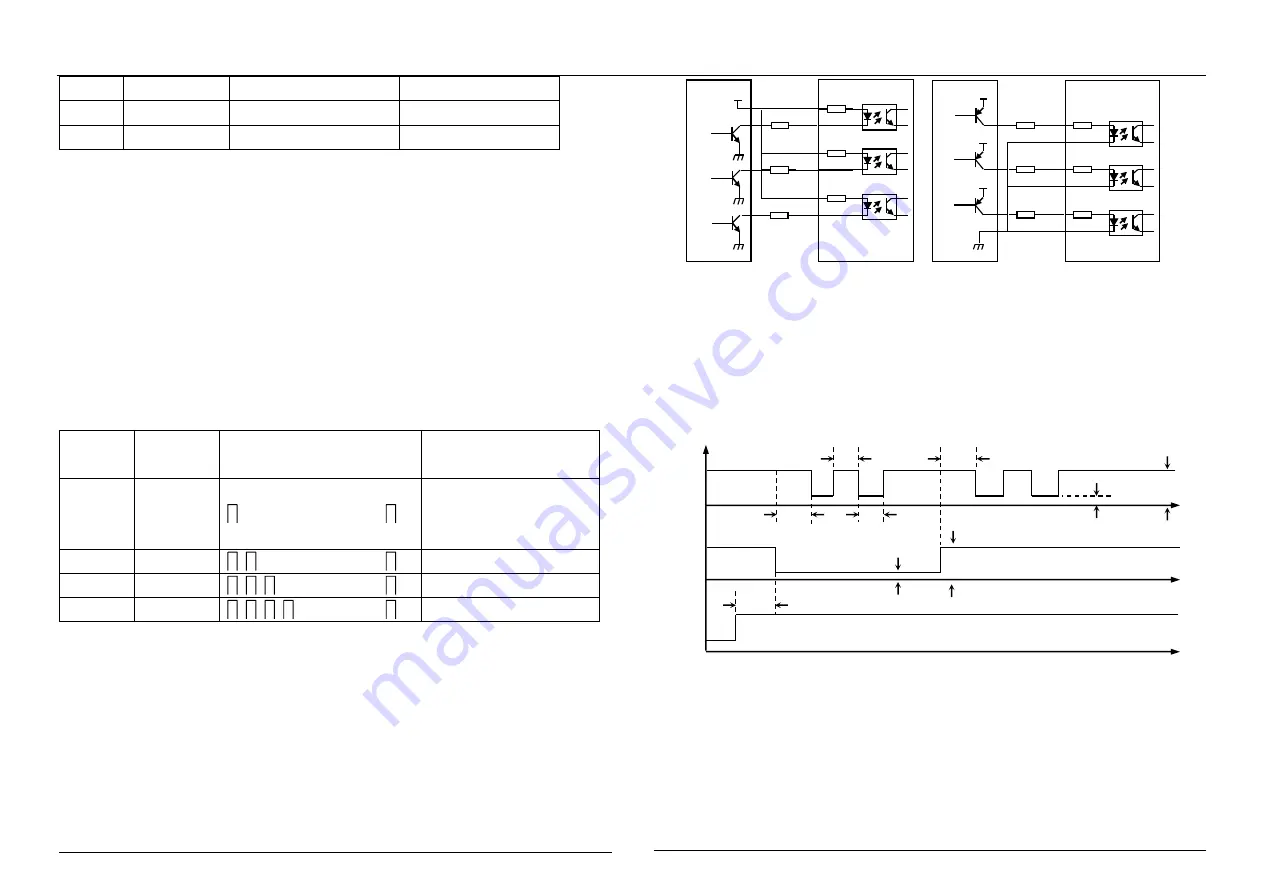

Control Signal Connector Interface

This FD430 driver uses differential inputs to increase noise immunity and interface

flexibility. Single-ended (common-cathode or common- anode) control signals from the

controller can also be accepted by this interface. The input circuit has built-in high-speed

opto-coupler, and can accept signals in the format of line driver, open-collector, or PNP

output. Recommend use line driver control signals to increase noise immunity of the

driver in interference environments.

In the following figures, connections to open-collector and PNP signals are illustrated.

Note: When VCC is 4.5V~28Vdc, R is connected or not.

3.

Sequence Chart of Control Signals

In order to avoid some fault operations and deviations, PUL, DIR and ENA should abide

by some rules, shown as following diagram:

Note

:

1

)

t1: ENA must be ahead of DIR by at least 5us. Determined high level. Usually,

ENA+ and ENA- are NC (not connected).

2

)

t2: DIR must be ahead of PUL active edge by 2ms to ensure correct direction;

3

)

t3: Pulse width not less than 2s;

4

)

t4: Low level width not less than 2us

.

270

Ω

270

Ω

270

Ω

Driver

PUL+

PUL-

DIR+

ENA+

DIR-

ENA-

VCC

R

R

R

脉冲信号

方向信号

使能信号

Common Anode connection

Common Cathode connection

270

Ω

270

Ω

270

Ω

Driver

PUL+

PUL-

DIR+

ENA+

DIR-

ENA-

VCC

R

R

R

脉冲信号

VCC

方向信号

VCC

使能信号

Figure 3: Input interface Circuit

t2

t4

t1

t3

t2

PUL

DIR

ENA

>2us

>2us

>5us

高电平高于

3.5V

高电平高于

3.5V

低电平低于

0.5V

低电平低于

0.5V

Figure 4 Sequence chart of control signals