User’s Manual for FD430 Digital 2-Phase Stepper Driver

User’s Manual for FD430 Digital 2-Phase Stepper Driver

5 6

Weight

Approx. 0.090 Kg

3.

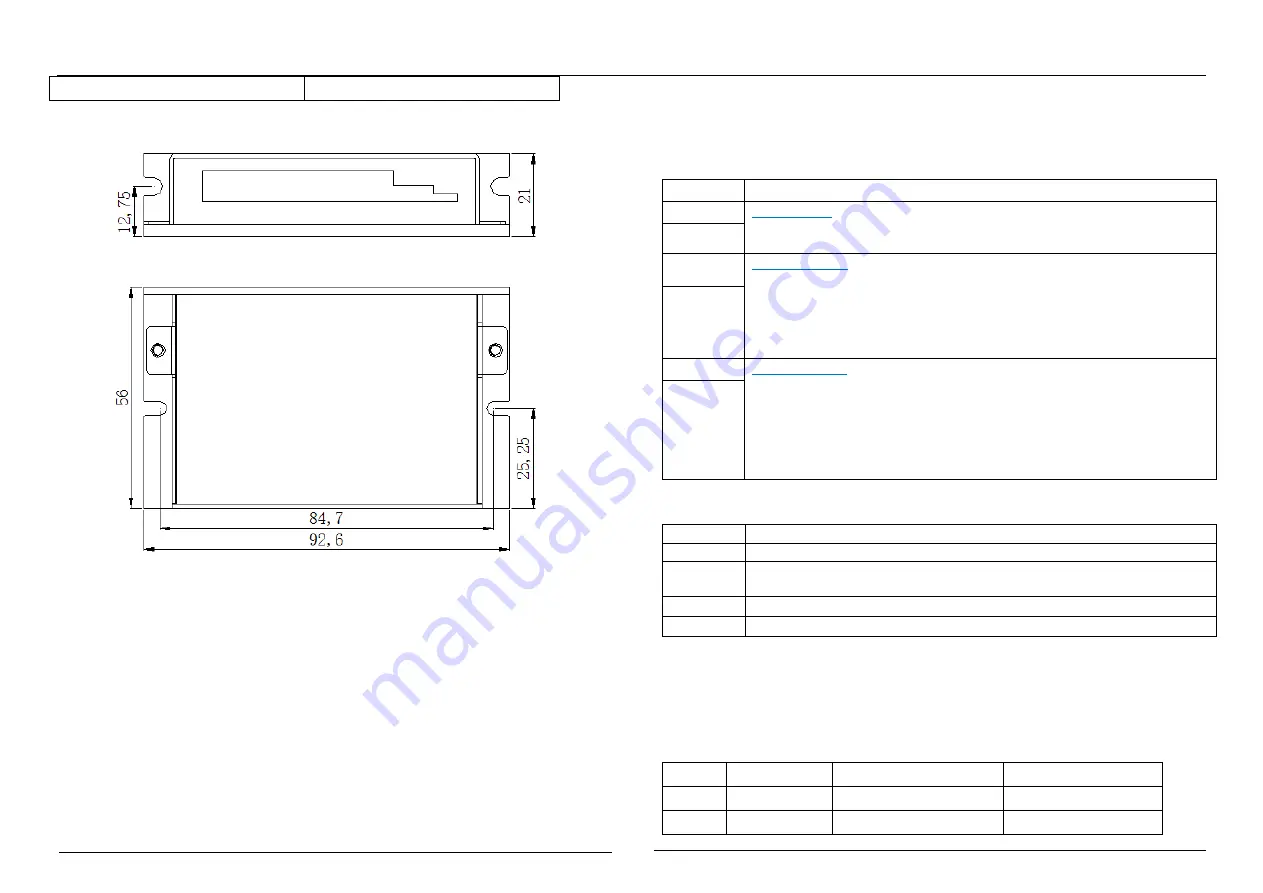

Mechanical Dimensions (unit: mm, 1 inch = 25.4 mm)

Figure 1: Mechanical dimensions

*Recommended to use side mounting for better heat dissipation, When designing

the installation size, pay attention to the terminal size and wiring.

4.

Elimination of Heat

1

)

Driver’s reliable working temperature should be <60

℃

, and motor working

temperature should be <80

℃

(176

℉

);

2

)

It is recommended to use automatic idle-current mode, namely current

automatically reduce to 50% when motor stops, so as to reduce driver heating and

motor heating;

3

)

It is recommended to mount the driver vertically to maximize heat sink area. Use

forced cooling method to cool the system if necessary, Ensure that the drives

operation in a reliable operating temperature range.

Ⅲ

. Pin Assignment and Description

1. Interface description

1

)

Control Signal Connector

Signal

Functions Details

PUL+

Pulse signal: This input represents pulse signal, each rising edge active,

4.5~28Vdc when PUL-HIGH, 0~0.5V when PUL-LOW, For reliable

response, pulse width should be longer than 1.5μs.

PUL-

DIR+

Direction signal: this signal has low/high voltage levels, representing two

directions of motor rotation; For reliable motion response, DIR signal

should be ahead of PUL signal by 2μs at least. 4.5V-28Vdc when

DIR-HIGH, 0-0.5V when DIR-LOW. Please note that rotation direction is

also related to motor-driver wiring match. Exchanging the connection of

two wires for a coil to the driver will reverse motion direction.

DIR-

ENA+

Enable signal:

This signal is used for enabling/disabling the driver. High

level for enabling the driver and low level for disabling the driver. When

ENA-HIGH is connected to 4.5V-28Vdc, ENA-LOW is connected to

0-0.5V (or Internal optical coupling is conducted), the driver will cut off

the current of each phase of the motor to make the motor in a free state,

step pulses are not responded at this time. Usually left

unconnected

(enabled)

.

ENA-

2

)

Power Connector Configurations

Signal

Functions Details

GND

Power Ground.

+Vdc

power supply, +12V~ +32Vdc Including voltage fluctuation and EMF

voltage, Recommended 24Vdc supply.

A+

、

A-

Motor coil A (leads A+ and A-)

B+

、

B-

Motor coil B (leads B+ and B-)

3

)

RS232/RS485 Communication Port

Special RS232 cable (Prohibition of charging plug) designed to setup

communication between the drive and PC-based configuration & tuning software

ProTuner. The PC software is used to configure the peak current, microstep, active level,

current loop parameters and the driver function, and so on.

Pin

Symbol

Name

Description

1

+5V

+5V power output

For external STU only

2

TxD

RS232 transmit