En-9

6.4. Wiring method

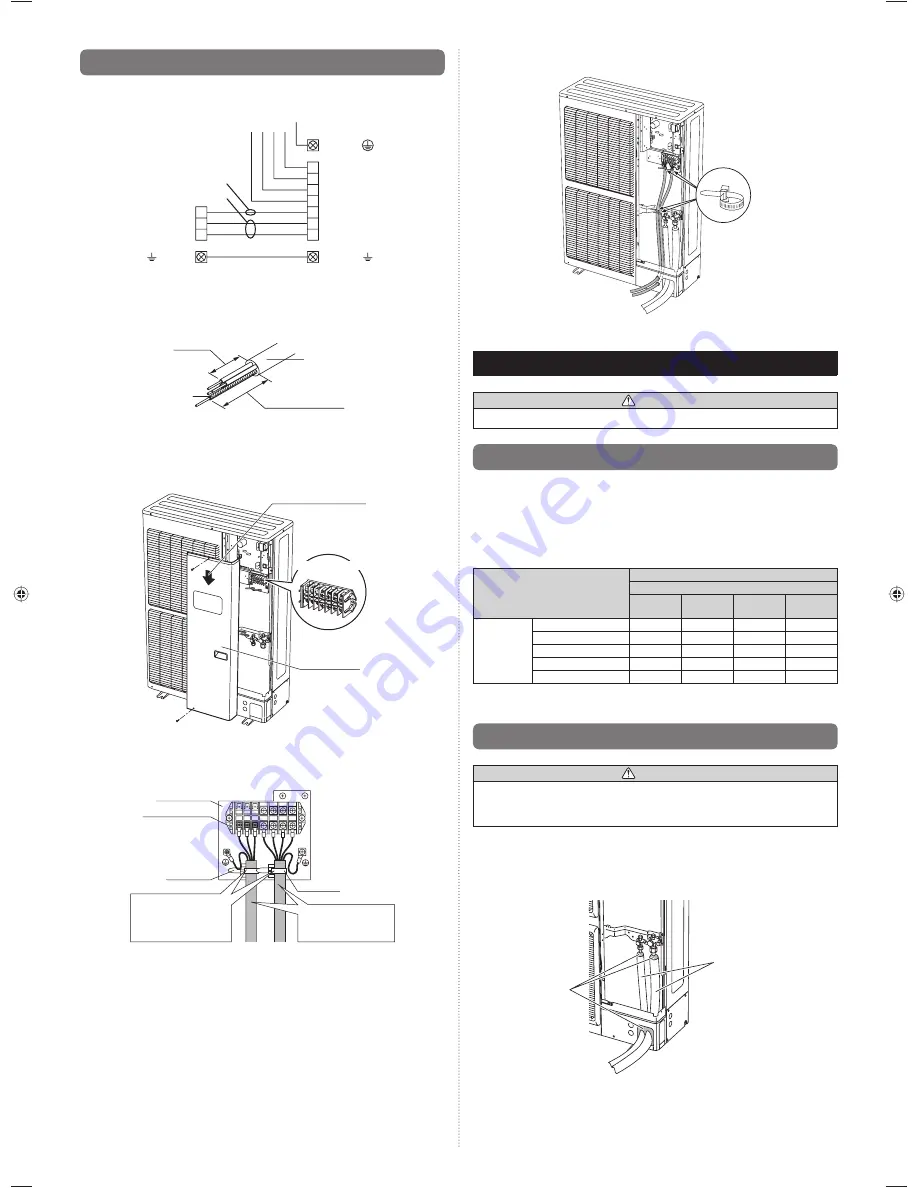

6.4.1. Connection diagrams

POWER SUPPLY

Indoor unit

side terminal

Outdoor unit

side terminal

N

L3

L2

L1

3

3

2

2

1

1

N

(T)

(S)

(R)

EARTH

(GROUND)

EARTH

(GROUND)

EARTH

(GROUND)

Earthing (Grounding) line

Power line

Control line

6.4.2. Connection cable preparation

Keep the earth (ground) wire longer than the other wires.

Earth (Ground) wire

40 mm

Power supply cable or

Transmission cable

60 mm or more

6.4.3. Wiring procedure

(1) Remove the service panel cover, insulation sheet and connect the wires to the

terminal in accordance with the terminal nameplate. (Fig. A, Fig. B)

Fig.

A

Direction of the service

panel removal

Terminal blocks

Service panel

(2) After connecting the wires, use cable clips to secure the wires. (Fig. B)

Connect the wires without applying excessive tension.

•

Fig.

B

Control box

Terminal blocks

Cable clip

Cable clip

Firmly secure the

cable clips so that the

wire terminals will not

receive external stress.

Use the speci

fi

ed wire

type and connect the

wires securely.

(3) Secure the cables using the cable clips under the terminal blocks, and then secure

the cables using the cable clips attached to the base of the valves.

Cable clip

(4) Be sure to install the insulation sheet after the wiring is complete.

s

d

7. PIPE INSTALLATION-2

WARNING

Install the insulated pipes so that they do not touch the compressor.

7.1. Installing insulation

Use an insulation on the refrigerant pipes to prevent condensation and dripping.

•

(Fig. A)

Determine the thickness of the insulation material by referring to Table A.

•

Table A, Selection of insulation

(for using an insulation material with equal heat transmission rate or below

0.040 W/(m·k))

Relative humidity

[mm (in.)]

Insulation material

Minimum thickness [mm]

70%

or more

75%

or more

80%

or more

85%

or more

Pipe

diameter

6.35 (1/4)

8

10

13

17

9.52 (3/8)

9

11

14

18

12.70 (1/2)

10

12

15

19

15.88 (5/8)

10

12

16

20

19.05 (3/4)

10

13

16

21

If the ambient temperature and relative humidity exceed 32 °C, increase the level of heat

insulation for the refrigerant pipes.

7.2. Filling with putty

WARNING

Fill the piping holes with putty (supplied locally) to avoid any gap (Fig. A). If small

animals such as insects enter the external unit, a short circuit may be caused near

electrical components in the service panel.

If the outdoor unit is installed at a level that is higher than the indoor unit, the water that

has condensed in the 3-way valve of the outdoor unit could travel to the indoor unit.

Therefore, use putty in the space between the pipe and the insulation to prevent the entry

of water.

Fig. A

Insulation

Putty

9379069403_IM.indb 9

9379069403_IM.indb 9

1/29/2013 4:44:20 PM

1/29/2013 4:44:20 PM