1.1 Functional description

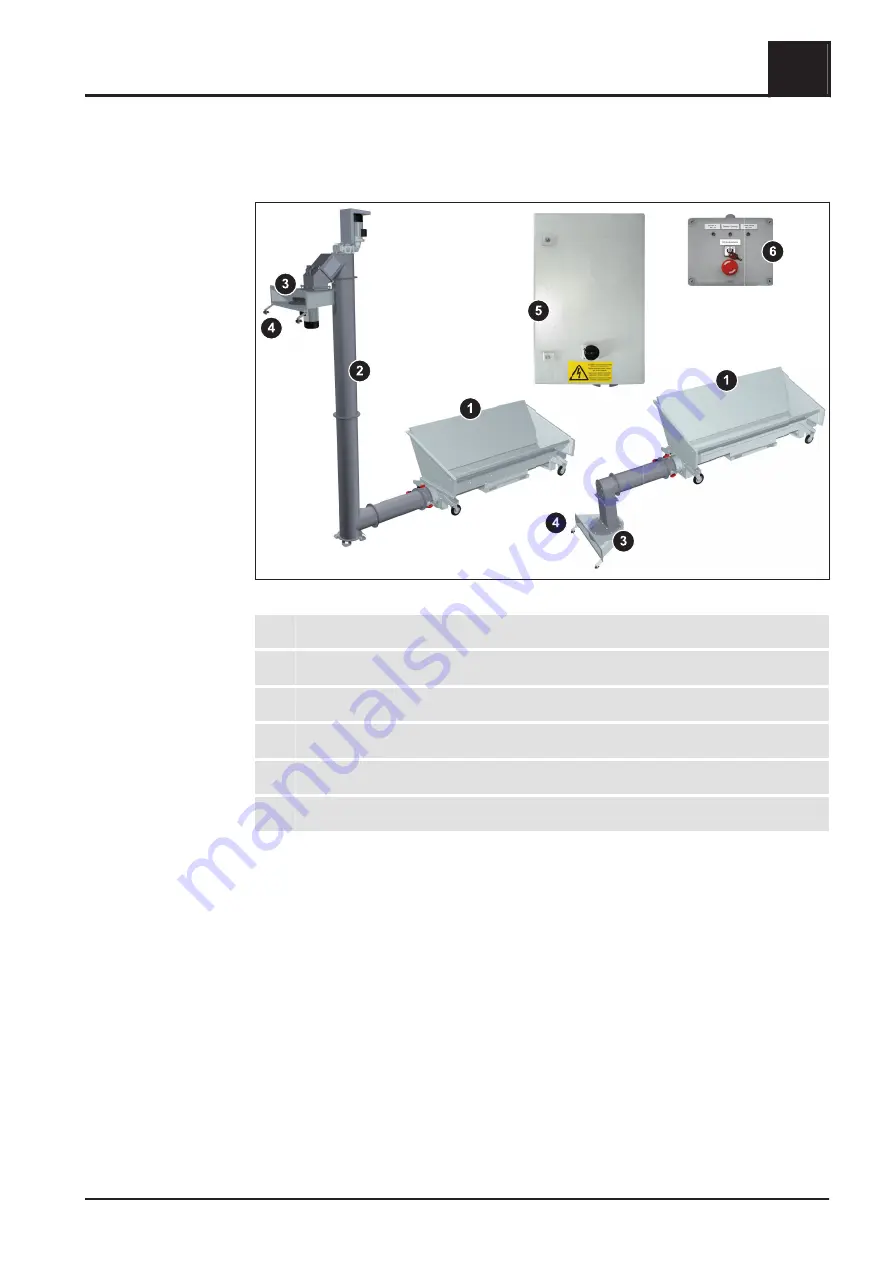

The Froling bunker filling system comprises:

BFSV

BFSU

1

Bulk chute

2

Vertical screw

3

Centrifugal disc

4

Filling level sensors

5

Switching unit with main switch

6

Control unit with control line, plug and mating plug (

)

The Froling bunker filling system has been designed for the automatic filling of a fuel

store. The bunker filling system, which can either be a stationary unit or equipped with

wheels, is loaded with fuel via the bulk chute (1) located outside the store space. The

system is started using the two-hand tripping device of the mobile control unit (6),

which is connected to the stationary control cabinet (5) via a flexible control line. The

horizontal screw of the bulk chute feeds the fuel to the transfer position. From there

the fuel is fed to the centrifugal disc (3) either directly (with BFSU) or via the vertical

screw (2 – with BFSU). The centrifugal action distributes the fuel in the store space.

The centrifugal disc is equipped with two filling level sensors (4), which are connected

to an LED display on the control. The two LEDs "Sensor right" and "Sensor left"

indicate whether the fuel in each area of the store space has reached the maximum

filling level. If a sensor responds, the direction of rotation of the centrifugal disc must

be changed manually.

General

1

Functional description

Installation- and Operating Intructions BFSV / BFSU | M1420116_en

5