S70-101SM

Page 12

Frick XJS and XJF Rotary Screw Compressor

Service Manual

1.2.1 JACKSHAFT AND GEARS – REMOVAL. (CONTD)

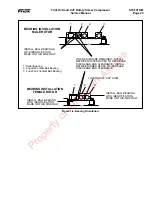

14. If necessary, remove inner race of roller bearing (11) from

jackshaft using Bearing Inner Race Puller (Owattona Tool Co.

p/n 1123).

6. Install retaining ring (12) in gear cover (52).

Ensure that tool is against outer

race and not against cage and bear-

ing rollers.

7. Install outer race of roller bearing (11) in gear cover.

Bearing can be installed by freezing and installing it in gear

cover or by using Discharge Ball Bearing Installation Tool

and rubber mallet. Ensure that roller bearing is tight against

retaining ring (12).

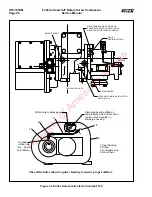

8. Slide jackshaft and gear set assembly (14) into gear cover

until inner race of roller bearing is seated under the rollers

of inner race bearing.

9. Using Jackshaft Bearing Installation Tool, press inboard

half of four-point contact ball bearing (9) inner race against

inner race of roller bearing (11).

DISCHARGE

BALL BEARING

INSTALLATION TOOL

JACKSHAFT AND GEAR

ASSEMBLY

JACKSHAFT BEARING

INSTALLATION TOOL

5. Heat inner race of roller bearing (11) to 250

O

F (121

O

C) for

one hour, and install race on jackshaft. Push inner race against

bearing spacer (13) and hold in place until bearing cools and

grips jackshaft.

Protective, heat-resistant gloves

must be worn when installing bear-

ing inner race.

3. Heat inner race of roller bearing (17) to

250×

F (232

×

C) for one

hour, and install race on jackshaft. Push inner race against bearing

spacer (16) and hold in place until race cools and grips jackshaft.

4. Install outer race of bearing (17) in rotor casing (22); secure

with retaining ring (15).

Protective, heat-resistant gloves

must be worn when installing bear-

ing inner race.

15. If necessary, remove inner race of roller bearing (17) from

jackshaft using Bearing Inner Race Puller.

16. Remove bearing spacer (16) from jackshaft.

17. Remove retaining ring (15) and outer race of roller bearing

(17) from rotor casing (22).

1.2.2 JACKSHAFT AND GEARS – INSTALLATION.

Jackshaft and gears installation shall be accomplished as follows:

NOTE: Index numbers refer to Figure 1-2, unless other-

wise noted.

1. Thoroughly clean all parts with OSHA approved, nonflam-

mable degreaser and clean, lint-free rags.

NOTE: If replacement Jackshaft Kit is used, steps 2

through 5 do not apply.

NOTE: In preparation for installing pinion gear in

step 12 heat gear to maximum 450

O

F (121

O

C) for approxi-

mately three hours..

2. Install bearing spacer (16) onto jackshaft (1) against main

gear (14).

CAUTION

WARNING

WARNING

Property of American Airlines