S70-101SM

Page 22

Frick XJS and XJF Rotary Screw Compressor

Service Manual

32. Install modified Female Distance Sleeve Tool (female

distance sleeve with center hole drilled out to

5

/

8

-inch) over

female rotor shaft and thread 5

1

/

2

-inch guide pin into end of

shaft. Install modified Outlet Bore Cover Tool (part of

Discharge Ball Bearing Removal Tool) with wave spring

(42) on discharge casing; secure with capscrews (8, Figure

1-4). Tighten capscrews to a torque value of 18 foot-pounds

(24.5 Nm).

33. With Air Cylinder Tool still attached to drive end of

compressor and using regulator to restrict air pressure to 35

psi max., take same measurements as in step 13, this section.

With bearing clamped, record female rotor “measured” end

play in Table 1.1 for future reference.

34. Remove modified Female Distance Sleeve Tool, guide

pin, and modified Outlet Bore Cover Tool from female rotor.

35. Install compression springs (37) in outlet bore cover

(39). Install new o-ring (27) on cover. Install male distance

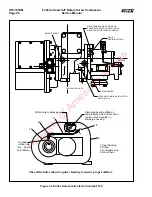

sleeve (38), with spring pin hole at 12 o’clock position in

outlet bore cover; secure with capscrews (8, Figure 1-4).

Tighten capscrews to a torque value of 18 foot-pounds (24.5

Nm). Ensure that spring pin (9, Figure 1-4) in cover

engages hole in male distance sleeve.

36. Install new o-ring (27) in outlet bore cover (41). Install

female distance sleeve (44), with roll pin hole at 7 o’clock

position, wave spring (42), and outlet bore cover; secure

with capscrews (8, Figure 1-4). Tighten capscrews to a

torque value of 18 foot-pounds (24.5 Nm). Ensure that

spring pin (40) in cover engages hole in female distance

sleeve.

37. Install slide valve and slide stop. (Refer to paragraph 1.3.2.)

38. Install jackshaft and gears. (Refer to paragraph 1.2.2.)

39. Install shaft seal. (Refer to paragraph 1.1.2.)

With bearing clamped, record male rotor “measured” end

play in Table 1.1 for future reference (should be within

.0015" - .003".

31. Remove modified Male Distance Sleeve Tool, guide pin,

and modified Outlet Bore Cover Tool from male rotor.

28. Install lockwasher (35) and locknut (36) on male rotor

shaft; tighten locknut with spanner wrench. Bend one tab of

lockwasher on end of male rotor shaft into one of the recesses

of locknut. This secures locknut in place and prevents it from

turning on rotor shaft.

29. Install modified Male Distance Sleeve Tool (male dis-

tance sleeve with center hole drilled out to

5

/

8

-inch) over male

rotor shaft and thread 3

1

/

2

-inch guide pin into end of shaft.

Install modified Outlet Bore Cover Tool (part of Discharge

Ball Bearing Removal Tool) with compression springs (37)

on discharge casing; secure with capscrews (8, Figure 1-4).

Tighten capscrews to a torque value of 18 foot-pounds (24.5

Nm).

30. With Air Cylinder Tool still attached to drive end of

compressor and using regulator to restrict air pressure to 35

psi max., take same measurements as in step 13, this section.

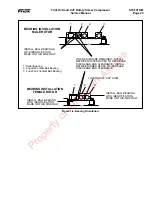

COMPRESSOR

DISCHARGE END

OUTBOARD HALF

(INNER RACE)

1.4.2 ROTORS AND BEARINGS – INSTALLATION. (CONTD)

outboard half of inner race of four-point contact ball bearing

on male rotor shaft.

INBOARD HALF

(INNER RACE)

DISCHARGE

BALL BEARING

INSTALLATION TOOL

26. Install outer race of four-point contact ball bearing (34) on

male rotor shaft.

27. Using Discharge Ball Bearing Installation Tool, install

25. Using Discharge Ball Bearing Installation Tool, install

inboard half of inner race of four-point contact ball bearing

(34) on male rotor shaft.

OUTLET BORE COVER

TOOL

CHECKING MALE ROTOR

“MEASURED” END PLAY

Property of American Airlines