S70-101SM

Page 13

Frick XJS and XJF Rotary Screw Compressor

Service Manual

10. Press outer race of four-point bearing into gear cover,

using seal housing (4); remove seal housing.

11. Using Jackshaft Bearing Installation Tool , press outboard

half of four-point contact ball bearing (9) inner race in place.

Protective, heat-resistant gloves

must be worn when installing bear-

ing inner race.

DO NOT force pinion gear into po-

sition. If pinion gear does not seat

properly on first attempt, remove,

reheat, and reinstall.

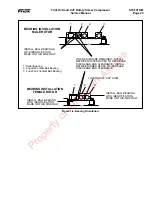

12. Install heated pinion gear on male rotor shaft (17). Push

pinion gear against shaft shoulder; hold in place until gear

cools and grips jackshaft.

PINION GEAR

13. Lubricate all internal compressor parts with a thin coat of

clean refrigerant oil.

NOTE: If 12mm guide pins were taken out after gear

cover was removed, reinstall pins in opposite sides of

casing, to facilitate cover installation.

14. Install new o-ring (51) in drive-end of rotor casing; use a

light coating of grease to hold o-ring place

It is important that jackshaft ro-

tates when cover is installed. If shaft

does not rotate, it may be binding

in roller bearing.

15. Install the gear cover and secure in place with capscrews

(7); tighten capscrews to a torque value of 58 foot-pounds (79

Nm). Remove guide pins.

Protective, heat-resistant gloves

must be worn when installing glyd-

ring.

Place section of shim material on in-

side of hose clamp to prevent pos-

sible damage caused by clamp holes.

16. If previously removed, install o-ring (11, Figure 1-4) and

glyd-ring (10, Figure 1-4) on slide stop piston (26, Figure 1-

4). To install glyd-ring, heat to 250

×

F (121

×

C) for one hour

and push into slot. Use a 4-inch (10 cm) hose clamp to hold

glyd-ring in place for 10 minutes.

Protective, heat-resistant gloves

must be worn when installing bear-

ing inner race.

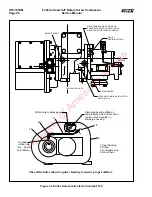

18. Place slide stop piston inside stepper piston. Thread 8mm

T-wrench into stepper piston; install stepper piston and slide

stop piston in compressor.

STEPPER PISTON

8MM T-WRENCH

19. Push stepper piston against spring force and remove 8mm

screw previously threaded into slide stop through drain hole;

keep hand pressure against piston and remove T-wrench.

20. Position slide stop cover (30, Figure 1-4), with new o-ring

(32, Figure 1-4) on gear housing (2, Figure 1-4); secure slide

stop cover to gear housing with capscrews (1). Tighten

capscrews to a torque value of 58 foot-pounds (79 Nm).

21. Install compressor drain plug (24, Figure 1-4).

22. Install flexible drive coupling. (Refer to S70-101 IOM.)

23. Evacuate compressor and oil separator. (Refer to S70-101

IOM.)

1.3 SLIDE VALVE AND SLIDE STOP. This procedure

provides the information necessary for qualified personnel to

replace the slide valve piston glyd-rings, including required

compressor disassembly.

1.3.1 SLIDE VALVE AND SLIDE STOP – REMOVAL.

Slide valve and slide stop removal shall be accomplished as

follows:

NOTE:

Index numbers refer to Figure 1-4, unless other

wise noted.

1. Evacuate compressor and oil separator. (Refer to S70-101

IOM.)

2. Remove coupling guard, if necessary.

3. Place suitable drain pan under compressor and remove oil

drain plug (24).

There is spring force behind slide

stop cover. Hold stepper piston (27)

in by hand.

WARNING

CAUTION

CAUTION

CAUTION

WARNING

WARNING

CAUTION

Property of American Airlines