140.960-IOM (JUN 2016)

Page 39

IDCF & IDC3 EVAPORATIVE CONDENSERS

OPERATION

NOTICE

The minimum turndown ratio for units with a belt drive

is 10:1 (or 6 hz). Units with the oil pump do not have a

minimum speed.

• Please refer to the manufacturer’s variable frequency drive

recommended start-up procedure for further information

or consult with your Frick sales representative for any VFD

applications.

RESONANT SPEED IDENTIFICATION PROCEDURE

There are several characteristic frequencies at which vibration

levels may resonate with unit structural components. These

include fan speed, motor speed, bearing frequency, and blade

pass frequency.

Within the overall operating speed range of a unit, it is not

unusual for one or more of these characteristic frequencies

to excite the structural components over relatively small

speed ranges and create an increase in vibration levels. If the

vibration levels are excessive at these resonant speeds, they

need to be locked out to prevent the VFD from operating the

motor at these speeds. The following procedure describes

how to identify the lockout speed ranges:

NOTICE

The resonant speed identification procedure must be per-

formed at start-up for units with VFDs.

• Ensure the VFD that controls the fan motor is off, and the

power to the motor circuit is locked out.

•

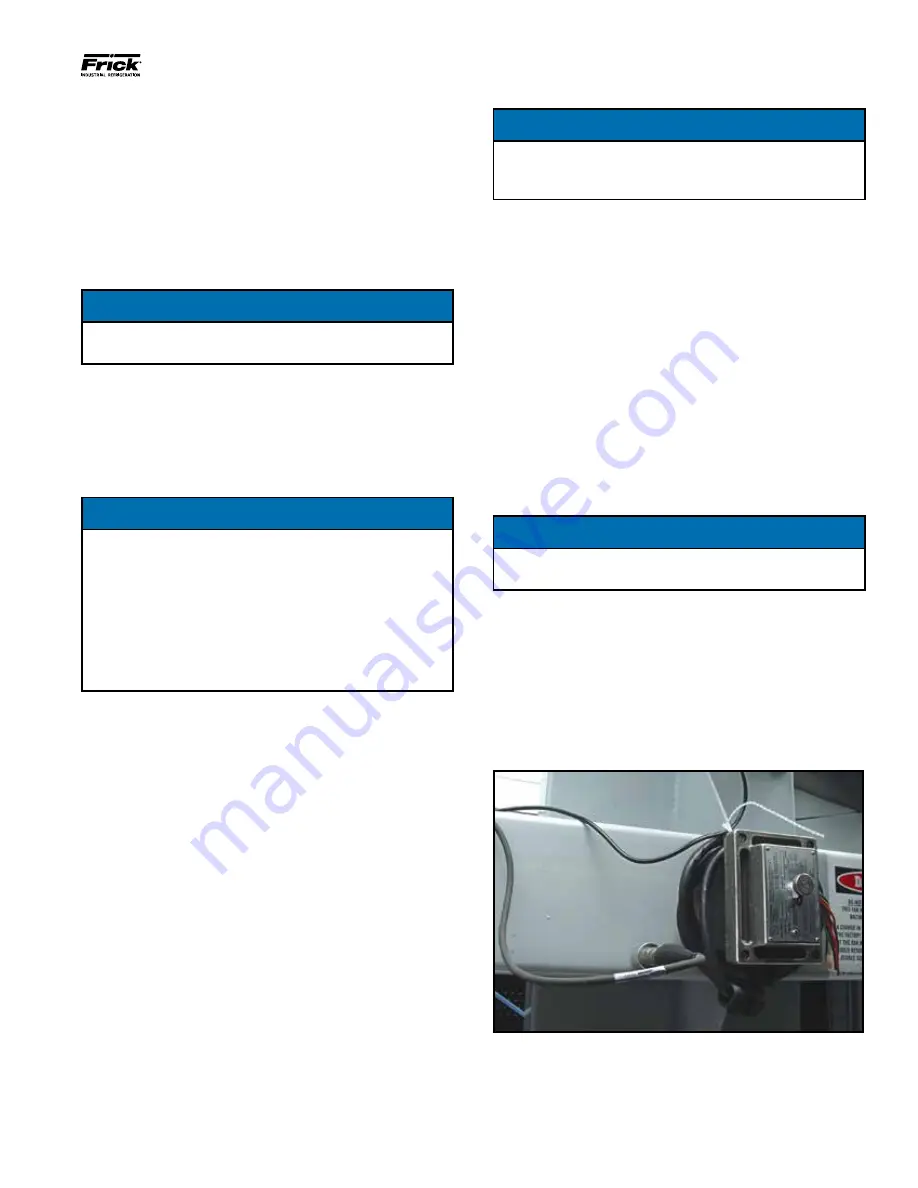

Attach the accelerometer (provided by

others) onto the box beam as shown in

Figure 10. The accelerometer should be located away

from the center of the web of the box beam, such that the

center line of the accelerometer is about 1 inch from the

upper or lower edge, as shown. On IDCF/IDC3-0406 and

-0412 units, the accelerometer should be located directly

on the motor base.

Figure 55 – Accelerometer Location - Belt Drive

INDEPENDENT FAN CONTROL (OPTIONAL)

Independent fan control is standard on 0412 and 0718 units

and optional on 1218, 2418, and 2436 units.

In an operating induced draft unit with independent fan

capabilities and no partitions, idle fans tend to windmill in the

reverse direction. A windmilling fan poses no threat to the

system while turning freely, but can create a large shock load

when the fan motor is suddenly powered up. Proper staging

of fans when starting from a windmilling condition will prevent

excessive stresses on the drive system.

NOTICE

With evaporative cooling, a 15 second fan motor delay will

not be noticed when staging up.

There are two control strategy options:

VFD

The recommended control option is to use a variable

frequency drive to control all of the motors. VFDs regulate

motor speed electronically and start motors with reduced

voltage and frequency. The result is a gentle motor start, and

therefore reduced stress.

NOTICE

For a unit with a VFD, with a switching frequency of 2.5

kHz, the line lead length cannot exceed 100 feet. If the

switching frequency is higher that 2.5 kHz and/or the line

lead length exceeds 100 feet, a dV/dT output filter is rec-

ommended to protect the motor.

Since the switching frequency and maximum line length

requirements vary between VFD and motor suppliers,

contact your Frick sales representative to determine if a

dV/dT filter is required.

No VFD

• Staging Up: Turn all motors off for 15 seconds. Following

the 15 second delay, bring all required fans online. Allow

for a 1 second time delay between fan stages to reduce

staging current.

• Staging Down: Turn off the fan motor. No need for delays.

VARIABLE FREQUENCY DRIVE

• Applications utilizing variable frequency drives (VFDs) for

fan motor control must use inverter duty motors built in

compliance with NEMA standard MG-1, Part 31.

• Operation of the unit at a speed which resonates with

components of the drive system or support structure may

result in vibrations which could damage the components

or structure, and/or create objectionable noise. Therefore,

these resonant speed ranges should be identified at start-

up and locked out to prevent operation of the motor at

these resonant speeds. Conduct the following “Resonant

Speed Identification Procedure."