HPS Rotary Screw Compressor Units

070.700-IOM (MAR 21)

Page 19

Installation

If the electronic control panel has a starter built into

the same panel, be sure to run the higher voltage wires

where indicated by the manufacturer.

EMI from the

wires can interfere with the electronics if run too close to

the circuitry.

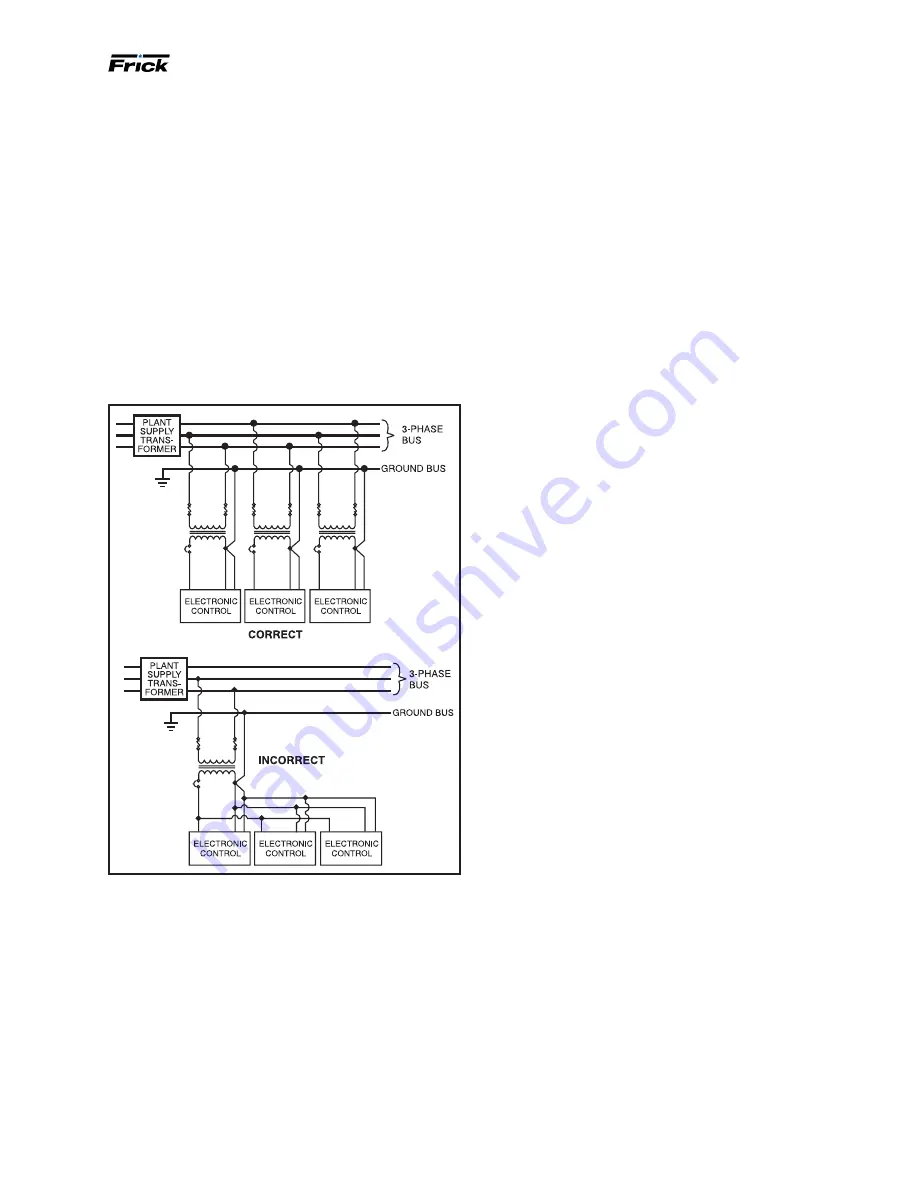

Never daisy-chain or parallel-connect power or ground

wires to electronic control panels.

Each electronic

control panel must have its own control power supply and

ground wires back to the power source (Plant Transform

-

er). Multiple electronic control panels on the same power

wires create current surges in the supply wires, which

may cause controller malfunctions. Daisy-chaining ground

wires, taking them to ground at each device, allows

ground loop currents to flow between electronic control

panels which also causes malfunctions. See the following

figure.

Figure 24: Daisy-chain wiring example

Communications

The use of communications such as serial and ethernet

in industrial environments are commonplace. The cor-

rect installation of these networks is as important to the

operation of the communications as all of the preceding

practices are to the equipment.

Serial communications cable needs to be the appropri-

ate gauge based on the total cable distance of the run.

Daisy-chaining is the only acceptable style of running the

communications cable. While Star Networks may use less

cable, they more often than not cause problems and inter-

ruptions in communications, due to varying impedances

over the varying lengths of cable. Ground or drain wires of

the communications cable are to be tied together at each

daisy-chain connection and only taken to ground in the

central control system panel.

It is important to carefully consider the type of cable to be

used. Just because a cable has the correct number of con-

ductors and is shielded does not mean it is an acceptable

cable. Johnson Controls-Frick suggests the use of Belden

#9829 for RS-422 communications and Belden # 9841 for

RS-485 up to 2000 ft (609.6 m) total cable length. Refer to

Frick drawing

649D4743

for more detail.

Comm Port Protection:

Surge suppression for the comm

ports may not be the best method, because suppression

is required to divert excess voltage/current to ground. The

success of these devices is dependent on a good ground

(covered earlier in this section). This excess energy can be

quite high and without a suitable ground, can access and

damage the port.

Isolation or Optical Isolation is the preferred comm port

protection method. With optical isolation, there is no con-

tinuity between the communications cable and the comm

port. There is no dependence on the quality of the ground.

Be sure to know what the

voltage isolation value of the

optical isolator is before selecting it. These may range

from 500 V to 4000 V.

Frick Optical Isolation Kits are available, part number

639C0133G01. One kit is required for each comm port.

UPS power and Quantum

™

HD

panels

Johnson Controls, Inc. does not advise nor support the

use of uninterrupted power supply systems for use with

the Quantum

™

HD panel. With a

UPS system providing

shutdown protection for a Frick Quantum panel, the panel

may not see the loss of the 3-phase voltage on the motor

because the UPS may prevent the motor starter contac-

tor from dropping out. With the starter contactor still

energized, the compressor auxiliary continues to feed an

“okay” signal to the

Quantum

™

HD panel. This may allow

the motor to be subjected to the fault condition on the

3-phase bus.

A couple of fault scenarios are: 1. The 3-phase bus has

power “on” and “off” in a continuous cycle manner which

may cause the motor to overheat due to repeated exces-

sive in-rush current experiences. 2. The motor cycling may

damage the coupling or cause other mechanical damage

due to the repeated high torque from rapid sequential

motor “bumps.” 3. Prolonged low voltage may cause the

motor to stall and possibly overheat before the motor

contactor is manually turned off.

Under normal conditions, the loss of 3-phase power shuts

down the Quantum

™

HD panel, restarting upon power

return.

•

Auto

– The

compressor motor starts running as pro

-

grammed.

•

Remote

– The external controller would reinitialize the

panel and proceed to run as required.