8

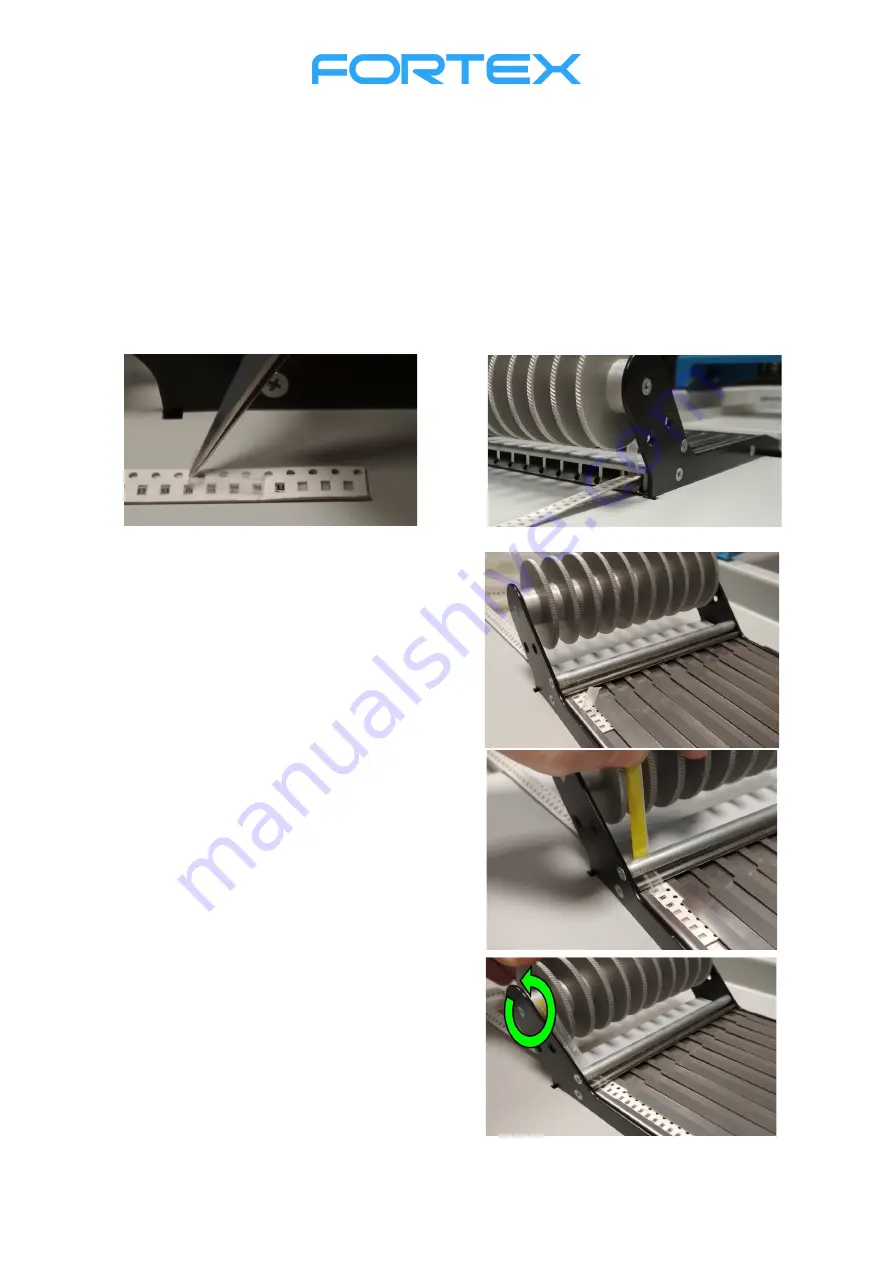

Feeder strapping

Important: It is recommended to perform this operation on the assembling desk. Always load

the strips according to the principle that the strips must be inserted into the feeder from left to

right, with the cover foil facing up and the holes in the strip on the far side from the operator.

Otherwise the picking of the components will be difficult and the tape foil will deform while

winding!

Before inserting the tape of SMD components to loading slot, peel the foil to 15-20 mm and insert it

into the slot under the winding wheel. (The foil can as well be peeled in the separating window in front

of the winding wheel and the bar using tweezers.)

Carefully slide the strip forward until it appears in the

separating window in front of the bar. Grasp the foil

and peel it to a length of 5-7 cm.

While foil is peeled, strip in the channel is moving

forward, so make sure that the components do not

pop out!

Drag the end of the foil under the bar in front of the

winding wheels. Stick the adhesive tape (size approx.

6 x 50 mm) on the free end of the foil, then stick the

foil onto the winding wheel so that it winds

anticlockwise. (Dragging the foil over the bar can

result in its rupture or an uneven movement of the

tape!)

Move SMD component tape forward carefully by foil

winding onto the winding wheel. If the strips are

damaged or broken, the strip may jam or slide heavily

(e.g. short-cut straps).