ENGLISH

7

Description of operation

Fogmaster foggers atomize liquids into small droplets (fog or mist)

by shearing them in a highly turbulent section of the nozzle. A blower in

the power head supplies air to create the turbulence.

The liquid flow into the nozzle, regulated by the control valve,

determines average fog droplet size. A low rate (1-2 ounces [30-60 ml]

per minute) produces a dry fog – small droplets that float extensively and

diffuse widely. A larger flow rate (4-8 ounces [100-250 ml] per minute)

produces progressively larger droplets (wet fog, fine mist).

Chemicals for disinfecting applications may require a dry fog (vapor

phase disinfectants) or a heavier fog to wet all surfaces and maintain liq-

uid contact for the time specified by the product label or information

sheet. Fogs are useful for this application because they diffuse widely, use

less chemical and speed up drying.

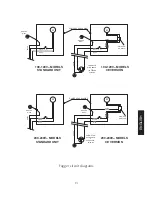

Measuring the Liquid flow rate

Adjust the angle of the nozzle for your application and adjust the

liquid control valve to obtain the desired fog droplet size characteristics. It

is often more convenient to fog with water to set an approximate flow

rate, then make final measurements using the fogging liquid.

Remove the power head from the tank. Place power head on a suit-

able stand, or suspend by its handle.

Fill a graduated cylinder or jar with a measured quantity of liquid.

Position the cylinder or jar so the liquid level is 6” [15 cm] below the fog-

ger nozzle and insert the suction tube.

Operate the fogger for 60 seconds. Remove suction tube, measure

remaining liquid and compute liquid consumed. This is the flow rate per

minute.

For small flow rates, you may have to operate longer than one min-

ute to get a good measurement.