ENGLISH

About motor brushes

Two graphite brushes convey electric power to the motor commuta-

tor. Brushes are a consumable item, and have a lifetime of about 650

operating hours. Operating without the air intake filter lets airborne dirt

and moisture enter the motor; this can reduce brush life substantially.

When brushes are worn the motor does not operate properly.

If you replace motor brushes, we recommend installing them in

pairs, and using

M

otor

S

aver

brushes. The

M

otor

S

aver

brush contains an

insulating pin to shut down the motor when the brush is worn,

minimizing the chance that the motor will drag and scratch the

commutator. Replacement brush part numbers are:

033: Brush kit (pair,

M

otor

S

aver

), 120 VAC.

034: Brush kit (pair,

M

otor

S

aver

), 240 VAC

How to replace motor brushes

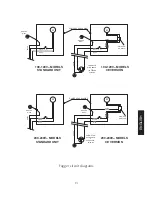

Unplug power cord to prevent shock. Remove front housing (see

“Simple Setup for Maintenance”) to access the motor. Identify the two

motor brush housings on opposite sides at the top of the motor.

Insert a small flat blade screwdriver between the motor wire/termi-

nal and the plastic brush housing. Gently pry terminal out, pushing it

towards the commutator until it is loosened. Take care not to break the

terminal contact or the wire. If the plastic brush housing is very tight, heat

slightly with a hair drier or heat gun to soften before sliding the wire/ter-

minal out. Repeat for the second brush.

Remove two Phillips head screws and retaining bracket holding one

motor brush. Lift brush off motor frame and discard.

Hold replacement brush in position with the tab pointed down.

Press the motor wire terminal (flat brass piece) partially into the brush

assembly, between the brass shell and the plastic housing.

Push the brush assembly towards the commutator until the tab falls

into the notch on the motor frame. Replace the retaining bracket and two

screws. Then slide or pry the wire terminator securely back into the brush

housing with the screwdriver.

Repeat for other brush.

11