Type of service

Purpose

Interval

Major overhaul

To secure a long operating

lifetime for the product. It

includes replacement of key

components and the

measures taken during an

inspection.

24,000 hours or 6 years, whichever comes first.

Applies to normal applications and operating

conditions at media (liquid) temperatures

< 40°C (104°F).

NOTICE:

Shorter intervals may be required when the operating conditions are extreme, for example with very

abrasive or corrosive applications or when the liquid temperatures exceed 40°C (104°F).

Inspection

CAUTION:

The inside may be pressurized. Be careful when opening the inspection covers.

Regular inspection and service of the pump ensures more reliable operation.

Do the following to service the pump:

Part to service

Action

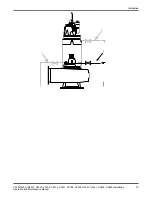

Pump casing

Check the entire pump and the cables for external mechanical damage.

Cable

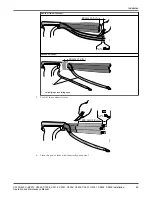

1. If the outer jacket is damaged, replace the cable.

2. Check that the cables do not have any sharp bends and are not pinched.

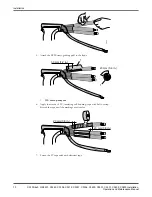

3. Check that the leads and cable entry screws are correctly connected and

tightened to the correct torque.

Lifting handle

Check the lifting handle for corrosion or other damage.

Junction box

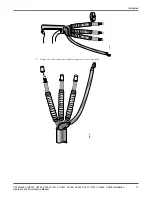

1. General:

Check that it is clean and dry.

If it is wet:

a.

Check the cable entry.

b. Replace the O-rings. (New O-rings should be fitted to all O-ring seal

joints opened during inspection.)

2. Terminal board: Check that the connections are properly tightened.

Junction box

insulation, drive units

up to 1.1 kV

Check the condition and function. See

Check the junction box insulation, up to 1.1

(page 84).

Junction box

insulation, drive units

1.2 - 6.6 kV

Check the condition and function. See

Check the junction box insulation, 1.2-6.6

(page 84).

Stator housing

1. Check that it is clean and dry:

• If there is oil in the stator housing, drain and clean. After one week of

operation, check again. If there is still oil in the stator housing, change

the seals.

• If there is water in the stator housing and there was water in the oil,

change the seals immediately.

• If there is water in the stator housing, but there was no water in the oil,

check all other connections.

2. Replace the O-rings.

Maintenance

82

C3300/6x5, C/R3231, C3240, C3306, C3312, C3351, C3356, C3400, C3501, C3531, C3602, C3800 Installation,

Operation and Maintenance Manual