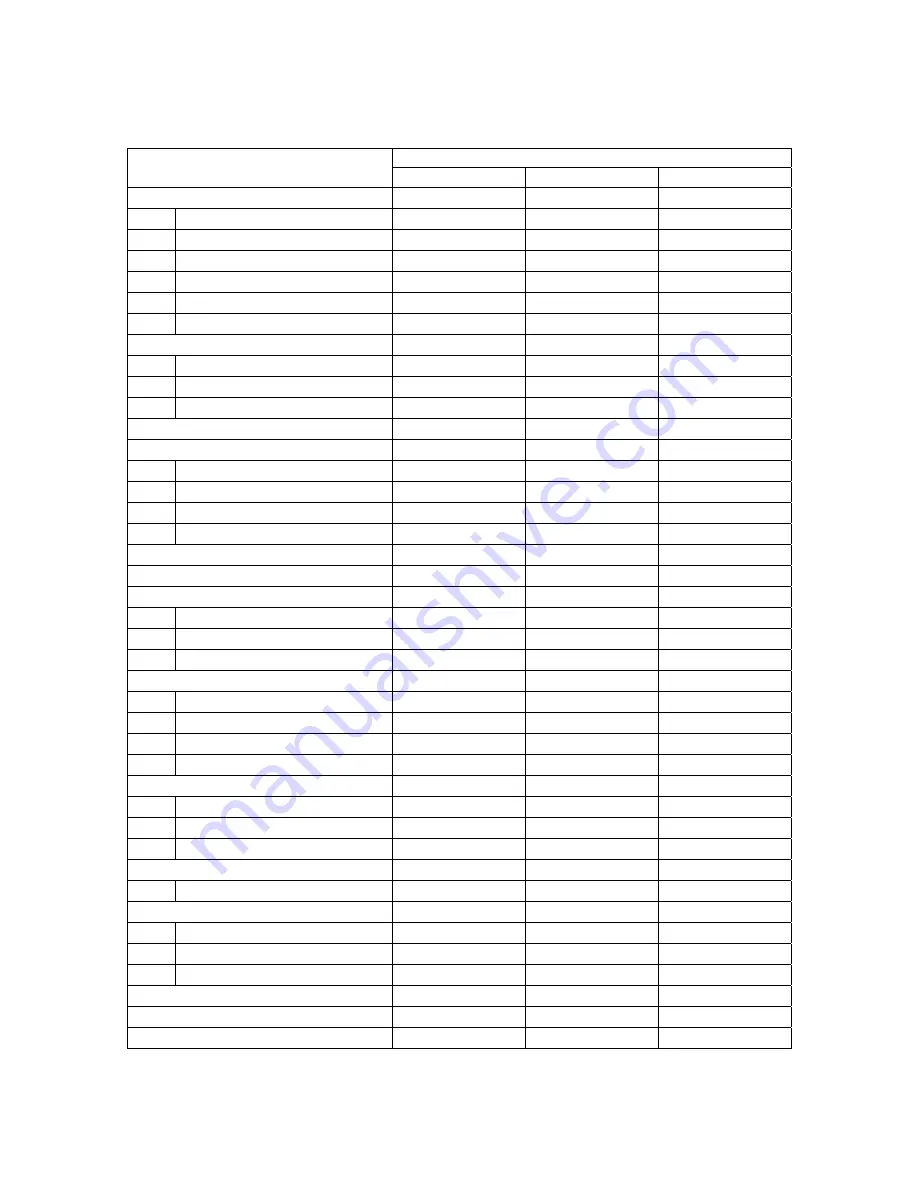

Table 1. Emissivity Values for Metals

Material Emissivity

1.0µm

1.6µm

8-14µm

Aluminum

Unoxidized

0.1-0.2

0.02-0.2

n.r.

Oxidized

0.4

0.4

0.2-0.4

Alloy

A3003,

Oxidized

n.r.

0.4

0.3

Roughened

0.2-0.8

0.2-0.6

0.1-0.3

Polished

0.1-0.2

0.02-0.1

n.r.

Brass

Polished

0.8-0.95

0.01-0.05

n.r.

Burnished

n.r.

n.r.

0.3

Oxidized

0.6

0.6

0.5

Chromium 0.4

0.4

n.r.

Copper

Polished

n.r. 0.03 n.r.

Roughened

n.r.

0.05-0.2

n.r

Oxidized

0.2-0.8

.2-0.9

0.4-0.8

Electrical Terminal Blocks

n.r.

n.r.

0.6

Gold 0.3

0.01-0.1

n.r.

Haynes Alloy

0.5-0.9

0.6-0.9

0.3-0.8

Inconel

Oxidized

0.4-0.9

0.6-0.9

0.7-0.95

Sandblasted

0.3-0.4

0.3-0.6

0.3-0.6

Electropolished

0.2-0.5

0.25

0.15

Iron

Oxidized

0.4-0.8

0.5-0.9

0.5-0.9

Unoxidized

0.35

0.1-0.3

n.r.

Rusted

n.r.

0.6-0.9

0.5-0.7

Molten

0.35

0.4-0.6

n.r.

Iron, Cast

Oxidized

0.7-0.9

0.7-0.9

0.6-0.95

Unoxidized

0.35

0.3

0.2

Molten

0.35

0.3-0.4

0.2-0.3

Iron, Wrought

Dull

0.9

0.9

0.9

Lead

Polished

0.35

0.05-0.2

n.r.

Rough

0.65

0.6

0.4

Oxidized

n.r.

0.3-0.7

0.2-0.6

Magnesium 0.3-0.8

0.05-0.3

n.r.

Mercury n.r.

0.05-0.15

n.r.

Molybdenum

Jan 31st, 2005

- 89 -

Summary of Contents for Ti30

Page 4: ...Appendix B Infrared Theory Q A 92 Glossary 96 Jan 31st 2005 4 ...

Page 25: ...Man Machine Interface Flow Charts Main Loop Jan 31st 2005 25 ...

Page 26: ...Image Recording Procedure Emissivity Adjustment Procedure Jan 31st 2005 26 ...

Page 70: ...Jan 31st 2005 70 ...

Page 86: ...Jan 31st 2005 86 ...