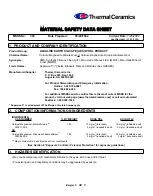

MATERIAL SAFETY DATA SHEET

MSDS No:

350

Date Prepared:

03/24/1992

Current Date:

7/26/2002

Last Revised:

(03/20/2002)

16. OTHER INFORMATION

SUPERWOOL

TM

DEVITRIFICATION

As produced, Superwools

TM

are vitreous (glassy) AES Wools that do not contain crystalline silica. Continued exposure

to elevated temperatures (>900

0

C) may cause these materials to form crystalline phases, including crystalline silica.

The occurrence and extent of crystalline silica formation is dependent on the duration and temperature of exposure,

CMS Wool chemistry and/or the presence of fluxing agents. The presence of crystalline silica can be confirmed only

through laboratory analysis of the "hot face" fiber. If crystalline silica is present, follow appropriate hygiene standards

and national regulations.

Devitrified, after-service Superwool

TM

, containing crystalline silica, has shown no adverse reactions in toxicity assays

(See Section 11). These findings are consistent with IARC’s evaluation, which states “Crystalline silica inhaled in the

form of quartz or cristobalite from occupational sources is carcinogenic to humans (Group 1)” and additionally notes

“carcinogenicity in humans was not detected in all industrial circumstances studied. Carcinogenicity may be dependent

on inherent characteristics of the crystalline silica or on external factors affecting its biological activity or distribution of

its polymorphs.” (IARC Monograph Vol. 68, 1997).

Respirable dust from devitrified Superwool

TM

products can be controlled with ventilation, dust collectors or respiratory

protection as detailed in Section 8 (above). Ventilation and respiratory protection should be provided in compliance with

OSHA standards. The evaluation of workplace hazards and, if necessary, the identification of appropriate respiratory

protection is best performed by qualified Industrial Hygienists.

For more information, call the Thermal Ceramics Product Stewardship Hotline (800-722-5681).

PRODUCT STEWARDSHIP PROGRAM

Morgan Thermal Ceramics has established a program to provide customers with up-to-date information regarding the

proper use and handling of Superwool

TM

. If you would like more information about this program, please call your local

supplier or visit one of the following web sites.

Thermal Ceramics - Global

www.thermalceramics.com

Refractory Ceramic Fibers Coalition (USA)

www.RCFC.net

ECFIA

(Europe)

www.ecfia.org

LABELING

As product information labels may be required on Superwool

TM

packages, check local destination regulations before

shipping.

HMIS HAZARD RATING

HMIS Health:

1

HMIS Flammable:

0

HMIS Reactivity:

0

HMIS Personal Protective:

To be determined by user

DEFINITIONS

Page 6 Of 7