8

Maintenance

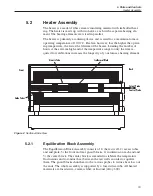

The calibration instrument has been designed with the utmost care. Ease of op-

eration and simplicity of maintenance have been a central theme in the product

development. Therefore, with proper care the instrument should require very

little maintenance. Avoid operating the instrument in an oily, wet, dirty, or

dusty environment.

•

If the outside of the instrument becomes soiled, it may be wiped clean

with a damp cloth and mild detergent. Do not use harsh chemicals on the

surface which may damage the paint.

•

Be sure that the well of the furnace is kept clean and clear of any foreign

matter.

Do not

use fluids to clean out the well.

•

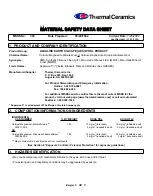

If a hazardous material is spilt on or inside the equipment, the user is re-

sponsible for taking the appropriate decontamination steps as outlined by

the national safety council with respect to the material.

•

If the mains supply cord becomes damaged, replace it with a cord with

the appropriate gauge wire for the current of the instrument. If there are

any questions, call Hart Scientific Customer Service for more informa-

tion.

•

Before using any cleaning or decontamination method except those rec-

ommended by Hart, users should check with Hart Scientific Customer

Service to be sure that the proposed method will not damage the equip-

ment.

•

If the instrument is used in a manner not in accordance with the equip-

ment design, the operation of the furnace may be impaired or safety haz-

ards may arise.

•

The over-temperature cut-out should be checked every 6 months to ensure

that it is working properly. Set the unit to 300°C and let it stabilize. Turn

the adjustable cutout knob down until the cutout is activated. Turn the

knob back up and push the reset button.

•

Periodically remove the equilibration block and use emery cloth to re-

move the oxidation build up on the block.

27

8 Maintenance