5.2

Heater Assembly

The heater is a made of fiber ceramic insulating material with imbedded heat-

ing. The heater is made up with two halves, each with a separate heating ele-

ment. The heating elements are wired in parallel.

The heater is primarily a radiating device and is rated for a maximum furnace

operating temperature of 1100°C. Realize, however, that the higher the operat-

ing temperature, the lower the lifetime of the heater. Limiting the number of

hours at the extreme high end of the temperature range to only the time re-

quired for calibrations increases the longevity of your furnace heating element.

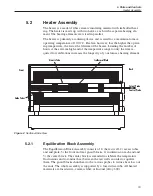

5.2.1

Equilibration Block Assembly

The Equilibration Block Assembly consists of 1) the test well, 2) access tubes

and end plate, 3) the front and rear guard blocks, 4) insulation on each end and

5) the center block. The center block is intended to stabilize the temperature

fluctuations and to conduct heat between the test wells in order to equalize

them. The guard blocks shunt heat to the various probes to reduce heat loss out

the ends. The whole assembly is supported by a fused silica tube. All heated

materials are fused silica, ceramic fiber, or Inconel (alloy 600).

19

5 Parts and Controls

Heater Assembly

Cutout Probe

Back

Isothermal Block

Quartz Tube

Front

Guide Tubes

Control Probe

Figure 2

Sectional Side View