21

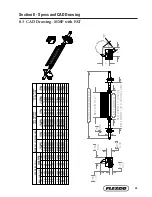

Section 8 - Specs and CAD Drawing

8.1 Specs and Guidelines

Specifications:

• Maximum Belt Speed ...................................................

5m/sec (1000 FPM)

• Temperature Rating ......................................................

35°C to 82°C (-30°F to 180°F)

• Minimum Pulley Diameter.........................................

400mm (16")

• Usable Blade Wear Length...........................................

150mm (6")

• Blade ................................................................................. Urethane (proprietary blend for

abrasion resistance and long wear)

• Available for Belt Widths .............................................

600 to 2400mm (24" to 96")

.

Other sizes available upon request.

• CEMA Cleaner Rating .................................................Class 4

Pole Location Specs

A = Pulley Di Lagging and Belt

C = Critical Spec to move location if necessary

A

X

C

Y

* Each pole size can be used with a blade size either belt

width minus 150mm (6"), belt width minus 300mm (12"), or

belt width minus (450) 18".

Move Dim. C on arc

Clearance Guidelines for Installation

Horizontal

Clearance Required

Vertical

Clearance Required

mm

in.

mm

in.

100

4

325

13

Pole Length Specifications*

Cleaner Size

Max Overall

Pole Length

Center Pole

Length

Maximum

Conveyor Span

mm

in.

mm

in.

mm

in.

mm

in.

600

24

2050

82

600

24

1650

66

750

30

2200

88

750

30

1800

72

900

36

2350

94

900

36

1950

78

1050

42

2500

100

1050

42

2100

84

1200

48

2650

106

1200

48

2250

90

1350

54

2800

112

1350

54

2400

96

1500

60

2950

118

1500

60

2550

102

1800

72

3250

130

1800

72

2850

114

2100

84

3550

142

2100

84

3150

126

2400

96

3850

154

2400

96

3450

138

* For special extra long pole length requirements a Pole Extender Kit (#76024) is available

that provides 750mm (30") of extended pole length.

Pole Location Chart

A

X

Y

C

400

204

305

367

425

218

305

375

450

231

305

383

475

244

305

390

500

259

305

400

525

274

305

410

550

288

305

419

575

300

305

428

600

315

305

438

625

328

305

448

650

341

305

457

675

353

305

467

700

366

305

476

725

380

305

487

775

392

305

497

775

403

305

506

825

417

305

517

825

432

305

528

850

444

305

539

875

457

305

549

900

469

305

559

925

483

305

571

950

496

305

582

975

508

305

592

1000

521

305

604

1025

533

305

614

1050

550

305

629

1075

569

305

646

1100

584

305

659

1125

601

305

674

1150

615

305

686

1175

632

305

702

1200

645

305

714

Pole Length

*

Max Conveyor Span

Vertical

Horizontal

Spring Length Chart

Blade

Width

Purple

Springs

White

Springs

Gold

Springs

Silver

Springs

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

450

18"

117

4 5/8"

152

6"

159

6 1/4"

6 1/2"

600

24"

102

4"

149

5 7/8"

159

6 1/4"

162

6 3/8"

750

30"

N/A

N/A

143

5 5/8"

156

6 1/8"

162

6 3/8"

900

36"

N/A

N/A

140

5 1/2"

152

6"

159

6 1/4"

1050

42"

N/A

N/A

133

5 1/4"

149

5 7/8"

159

6 1/4"

1200

48"

N/A

N/A

130

5 1/8"

146

5 3/4"

155

6 1/8"

1350

54"

N/A

N/A

124

4 7/8"

143

5 5/8"

155

6 1/8"

1500

60"

N/A

N/A

121

4 3/4"

143

5 5/8"

155

6 1/8"

1650

66"

N/A

N/A

N/A

N/A

140

5 1/2"

152

6"

1800

72"

N/A

N/A

N/A

N/A

137

5 3/8"

152

6"

1950

78"

N/A

N/A

N/A

N/A

133

5 1/4"

149

5 7/8"

2100

84"

N/A

N/A

N/A

N/A

130

5 1/8"

149

5 7/8"

2150

90"

N/A

N/A

N/A

N/A

N/A

N/A

146

5 3/4"

2400

96"

N/A

N/A

N/A

N/A

N/A

N/A

143

5 5/8"

2550

102"

N/A

N/A

N/A

N/A

N/A

N/A

140

5 1/2"

2700

108"

N/A

N/A

N/A

N/A

N/A

N/A

140

5 1/2"

2850

114"

N/A

N/A

N/A

N/A

N/A

N/A

137

5 3/8"

Shading indicates preferred spring option.

Top of

washer

to top of

torque arm

Pressure Chart

Blade

Width

MPa PSI*

mm.

in.

450

18"

.034

5#

600

24"

.041

6#

800

32"

.055

8#

900

36"

.062

9#

1050

42"

.076

11#

1200

48"

.090

13#

1350

54"

.097

14#

1500

60"

.110

16#

1650

66"

.117

17#

1800

72"

.131

19#

1950

78"

.145

21#

2100

84"

.152

22#

2250

90"

.165

24#

2400

96"

.172

25#

2550

102"

.186

27#

2700

108"

.193

28#

2850

114"

.207

30#

* PSI setting is based on the

belt width.

Summary of Contents for MMP Precleaner

Page 1: ...www flexco com Installation Operation and Maintenance Manual MMP Precleaner...

Page 25: ......

Page 26: ......