13

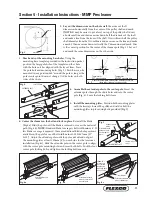

Fig. 8P

NOTE: PAT Tensioners are shipped with the air bags and torque arms

attached to the mounting bases.

7P. Tension the blades to the belt. Collapse both air bags (with

C-clamps) and rotate the blades until they are 25mm (1") short

of contact with the belt. Tighten the torque arm locking bolts and

jam nuts (Fig. 7P).

8P. Connect the supply lines and set

tension pressure. With the parts

supplied, attach a line to each air bag

and run the lines to the outlet side of

the control box (Fig. 8P). NOTE: Be

sure lines are safely away from the

belt. Connect a line from the inlet

side of the box to the site’s supply,

or air tank. Test the connections for

leaks and set the pressure per the

chart on the control box (also shown

to right).

9P. Test run the cleaner. Run the conveyor for at least 15 minutes and

inspect cleaning performance. Make adjustments as necessary.

Portable Air Tensioner (PAT)

Connect line

from site supply

or tank

Connect lines

from air bags

PAT Control Box

Section 4 - Installation Instructions - MMP Precleaner (cont.)

Fig. 7P

Torque arm

locking bolts

and jam nuts

Collapse

air bags

Pressure Chart

Blade

Width

MPa PSI*

mm.

in.

450

18"

.034

5#

600

24"

.041

6#

800

32"

.055

8#

900

36"

.062

9#

1050

42"

.076

11#

1200

48"

.090

13#

1350

54"

.097

14#

1500

60"

.110

16#

1650

66"

.117

17#

1800

72"

.131

19#

1950

78"

.145

21#

2100

84"

.152

22#

2250

90"

.165

24#

2400

96"

.172

25#

2550

102"

.186

27#

2700

108"

.193

28#

2850

114"

.207

30#

* PSI setting is based on the

belt width.

Summary of Contents for MMP Precleaner

Page 1: ...www flexco com Installation Operation and Maintenance Manual MMP Precleaner...

Page 25: ......

Page 26: ......