24

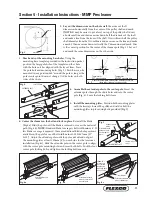

MMP Precleaner

Section 9 - Replacement Parts

For best results use Flexco

®

Genuine

Replacement Blades and Parts.

Replacement Parts

Ref Description

Ordering

Number

Item

Code

WT.

KG.

1

600mm (24") Center Pole

MMPCP24

76458

15.6

750mm (30") Center Pole

MMPCP30

76459

19.5

900mm (36") Center Pole

MMPCP36

76460

23.4

1050mm (42") Center Pole

MMPCP42

76461

27.3

1200mm (48") Center Pole

MMPCP48

76462

31.2

1350mm (54") Center Pole

MMPCP54

76463

35.1

1500mm (60") Center Pole

MMPCP60

76464

39

1800mm (72") Center Pole

MMPCP72

76465

46.8

2100mm (84") Center Pole

MMPCP84

76808

54.6

2400mm (96") Center Pole

MMPCP96

77722

62.4

2

Extender Pole Kit

(2 ea.)

MHP-EP

76392

24.5

3

Mounting Plate Kit*

(2 ea.)

MSPMPK

75811

3.8

4

Blade Pin Kit*

(1 ea.)

MMPBPK

76466

0.4

5

Pivot Arm Kit*

(1 ea.)

QMTPAK

76096

2.0

6

Tension Spring - Purple

(1 ea.)

for blades 600mm (24")

QMTS-P

75845

.3

6a

Tension Spring - White

(1 ea.)

for blades 750 - 1200mm (30" - 48")

PSTS-W

75898

.8

6b

Tension Spring - Gold

(1 ea.)

for blades 1350 - 2250mm (54" - 90")

QMTS-G

76484

1.1

7

Bushing Kit - Purple

(2 ea.)

QMTBK-P

76097

.05

7a

Bushing Kit - White & Silver

(2 ea.)

QMTBK-W

76098

.1

7b

Bushing Kit - Gold

(2 ea.)

QMTBK-G

76540

.1

8

Pivot Shaft Bracket Kit*

(1 ea.)

QMTPSBK

76099

2.0

9

Torsion Arm Kit*

(1 ea.)

PSTA

75896

5.2

-

QMT Spring Tensioner* - Purple

(incl. 1 ea. Items 5, 6, 7, 8, & 9)

for blades 450 - 600mm (18" - 24")

QMT-P

76074

9.3

-

QMT Spring Tensioner* - White

(incl. 1 ea. Items 5, 6a, 7a, 8, & 9)

for blades 750 - 1200mm (30" - 48")

QMT-W

76075

9.9

-

QMT Spring Tensioner* - Gold

(incl. 1 ea. Items 5, 6b, 7b, 8, & 9)

for blades 1350 - 1950mm (54" - 78")

QMT-G

76483

10.5

10

Air/Water Bag

(1 ea.)

AWTB

75905

1.7

11

Mounting Base

(1ea.)

AWTMB

75906

10.4

12

Torque Arm*

(1 ea.)

AWTA

75907

5.3

13

Hose Kit

(15M (50') of hose and 6 hose clamps)

AWTHK

75909

3.0

14

PAT Control Box

PACB

78683

5.0

15

AWT Pole Bearing Assy

(For cleaners shipped after 4/2016)

AWTPBA

90000

2.3

-

PAT Kit- AWT Tensioner w/ Control Box

(in-

cludes 2 ea. Items 10,11,12,13 & 1 ea. Item 14)

PAK

78705

39.1

-

AWT Air/Water Tensioner w/o Control Box

(includes 2 ea. Items 10,11,12 & 13)

AWTNCB

76069

34.1

*Hardware Included

Lead Time: 1 working day

Replacement TuffShear Blades

Ref

Blade Width

Ordering

Number

Item

Code

Wt.

Kg.

in.

mm

16

18

450

TRB18

76485

9.5

24

600

TRB24

76486

12.7

30

750

TRB30

76487

15.9

36

900

TRB36

76488

19.1

42

1050

TRB42

76489

22.2

48

1200

TRB48

76490

25.4

54

1350

TRB54

76491

28.6

60

1500

TRB60

76492

31.8

66

1650

TRB66

76493

34.9

72

1800

TRB72

76494

38.1

78

1950

TRB78

76697

41.3

84

2100

TRB84

77047

44.5

90

2250

TRB90

77048

47.6

Order blade width for your belt width’s material path: Belt Width Minus 150mm

(6"), Belt Width Minus 300mm (12") or Belt Width Minus 450mm (18").

Lead Time: 1 working day

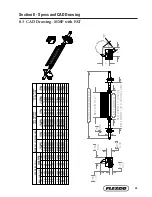

14

10

12

13

11

Spring Tensioner Selection Chart

CLEANER

BLADE WIDTH

76074

QMT-P

76075

QMT-W

76483

QMT-G

79039

QMT-S

TuffShear 450 - 600mm

(18" - 24")

X

TuffShear 750 - 1200mm

(30" - 48")

X

TuffShear 1350 - 1950mm

(54" - 78")

X

TuffShear 2100-2250mm

(84" - 90")

X

6

2

6a 6b

Detail view of Item 4

3

16

7 7a

4

1

8

5

9

7b

15

Summary of Contents for MMP Precleaner

Page 1: ...www flexco com Installation Operation and Maintenance Manual MMP Precleaner...

Page 25: ......

Page 26: ......