FALCON II

24

6. MAINTENANCE AND CLEANING

The following operations must be carried out by Corgi registered engineers only.

6.01 Annual Servicing

The following should be checked at least once a year:

• Water pressure in the central heating system when cold should be about 1 bar. If this is not the case,

bring it back to this value.

• Check control and safety devices (gas valve, flow meter, thermostats, etc) are functioning correctly.

• The burner and heat exchanger must be clean. To avoid damage, always clean them with a soft brush or

compressed air. Never use chemical products.

• The expansion vessel must be checked (precharge 1 bar).

• Check there are no leaks in the gas and water circuits.

• Check the air-flue gas duct terminal is free from obstructions and sound.

• The electrodes must be free from corrosion build up and correctly positioned.

• Gas flow and pressure must correspond to the values given in the Technical Data (page 5).

• The pump must be free to rotate.

6.02 Cleaning the boiler and burner

The boiler should be serviced annually. The heat exchanger and burner must never be cleaned with chemical

products or steel brushes. Particular attention must be paid to all seals and fixings associated with the

room-sealed compartment (gaskets, grommets, etc). Air leakage would cause pressure inside the compartment

to drop, possibly tripping the differential pressure switch and thus shutting down the boiler. After cleaning

particular attention should also be paid to checking stages of start-up and operation of the thermostats,

gas valve and pump.

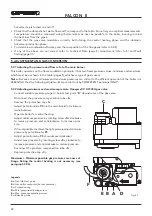

6.03 Servicing procedure

1. Visually check boiler for correct intallation and flueing.

2. Isolate electricity check fuse is 3amp.

3. Remove case by undoing the two screws locate at the bottom rear corners, lift slightly and pull forward.

4. Carry out preliminary electrical checks at boiler junction box. This is located in the centre of the boiler

at the bottom and can be accessed be the removal of a single screw. Any faults found must be rectified

before proceeding.

5. If electrical checks prove O.K. replace cover and secure with screw.

6. Attach a manometer to the boiler gas inlet test point, turn on electricty and fire boiler for hot water, check

inlet pressure. This should be 20mbar

minimum

for NG and 37mbar for LPG. If this is not the case there is a

supply problem and this will need to be remedied.

7. If inlet pressure is O.K. shut down boiler and remove manometer from gas inlet pressure test point and attach

it to the boiler burner pressure test point. Reseal inlet pressure test point.

8. Fire boiler for hot water and check that the maximum pressure is 13.0mbar for NG and 35.5mbar for LPG.

Turn off tap. Turn P3 on the main circuit board to minimum and fixe the boiler for heating, check that the

burner pressure reads 2.5 mbar for NG and 7.0mbar for LPG. Turn P3 back to max position. Shut down boiler,

remove manometer, seal test point and re-attach modureg lead. If the pressures are not as specified they will

need to be adjusted on the gas valve(see page 22 - installation manual).

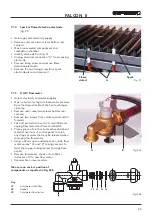

10. Remove fan by undoing the two fan securing screws tilt the front of the fan upwards to detach it from the

securing pin and withdraw it from the boiler, disconnect the wires and air pressure switch tubes.

11. Take off the combustion chamber cover by removing the three securing screws.

12. Lift off flue hood and flue baffle plate.

13. Pull off the ignition and flame rectification leads from their respective electrodes.

14. Undo the gas union in the centre of burner rail and take out the two securing screws. Remove the burner

rail and clean rail and injectors.

15. Remove two screws securing the burner assembly and remove the assembly. Clean burners.