Installation & Operating Instructions

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

Page 7

www.fptgroup.com

Fenner is a registered trademark of J.H. Fenner & Co. Limited

ııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııııı

Page 6

www.fptgroup.com

Fenner is a registered trademark of J.H. Fenner & Co. Limited

Installation & Operating Instructions

3. M

ECHANICAL

I

NSTALLATION

3.1. G

ENERAL

• Store the Fenner QD:E drive in its box until required. Storage should be clean and dry and within the temperature range –40°C to +60°C

• Install the Fenner drive on a flat, vertical, flame-resistant, vibration-free mounting within a suitable enclosure, according to

EN60529 if specific Ingress Protection ratings are required

• The drive must be installed in a pollution degree 1 or 2 environment

• Sizes 1 & 2 are DIN rail mountable, Size 3 is not DIN rail mountable.

• Ensure that all terminals are tightened to the appropriate torque setting

3.2. M

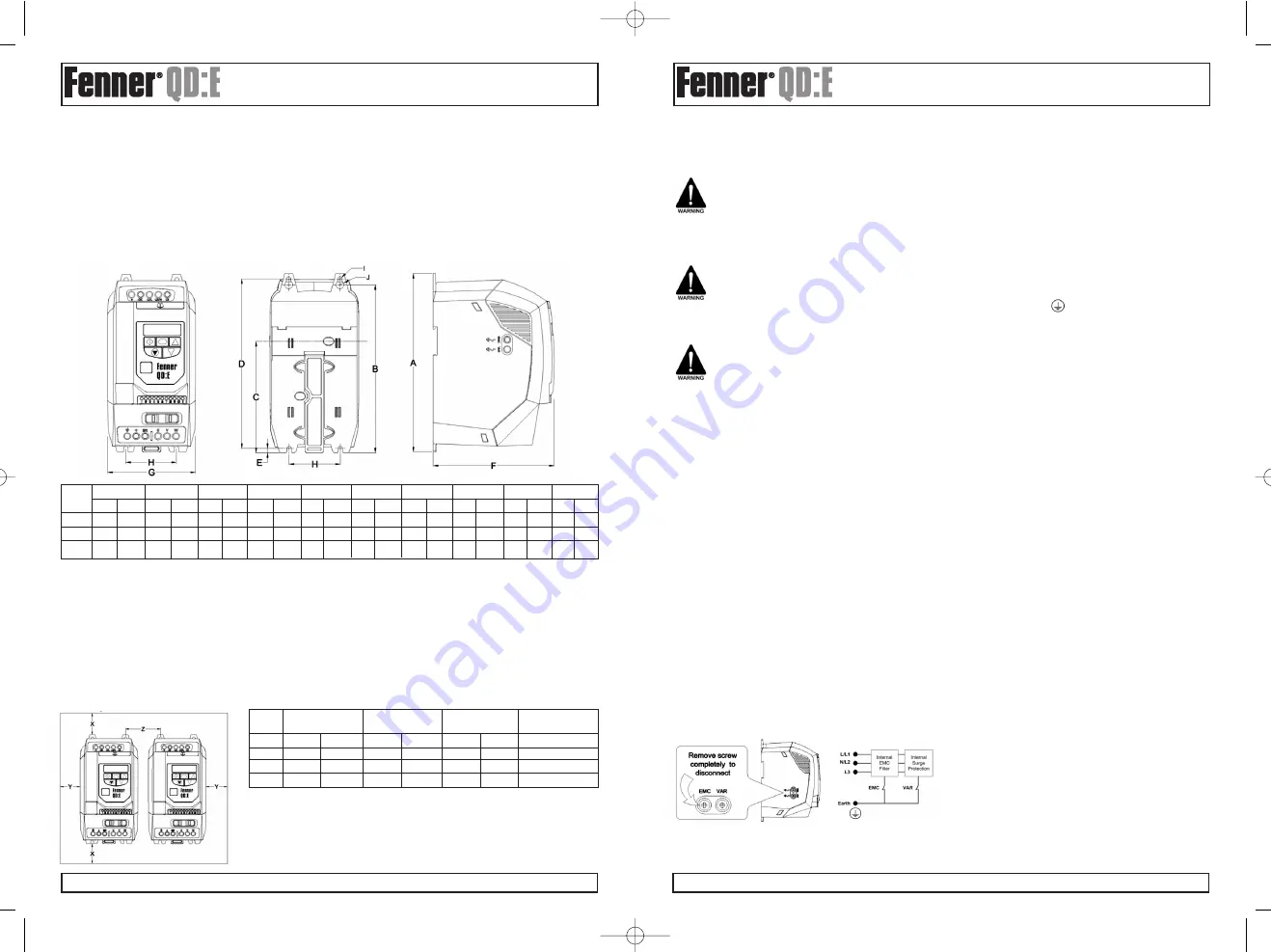

ECHANICAL DIMENSIONS AND MOUNTING

Drive

A B

C D

E

F G

H I

J

Size

mm in mm in mm

in mm

in mm in mm in mm in mm in mm in mm in

1 173 6.81 160 6.30 109 4.29 162

6.38 5.0 0.20 123 4.84 82 3.23 50 1.97 5.5 0.22 10

0.39

2 221 8.70 207 8.15 137 5.39 209 8.23 5.3 0.21 150 5.91 109 4.29 63 2.48 5.5 0.22 10 0.39

3 261 10.28 246 9.69 -

- 247 9.72 6.0 0.24 175 6.89 131 5.16 80 3.15 5.5 0.22 10 0.39

Control Terminal Torque Settings of 0.5 Nm (4.5 lb-in)

Power Terminal Torque Settings of 1 Nm (9 lb-in)

3.3. E

NCLOSURE MOUNTING

For applications that require a higher IP rating than the IP20 offered by the standard drive, the drive must be mounted in a

metallic enclosure. The following guidelines should be observed for these applications:

• Enclosures should be made from a thermally conductive material.

• When vented enclosures are used, there should be venting above the drive and below the drive to ensure good air

circulation. Air should be drawn in below the drive and expelled above the drive.

• If the external environment contains contamination particles (e.g. dust), a suitable particle filter should be fitted to the vents

and forced ventilation implemented. The filter must be serviced / cleaned appropriately.

• High moisture, salt or chemical content environments should use a suitably sealed (non-vented) enclosure.

Drive

X Y

Z

Recommended

Size Above/Below

Either

Side

Between

airflow

mm in mm in mm in CFM

(ft

3

/min)

1 50

1.97

50

1.97

33

1.30

11

2 75

2.95

50

1.97

46

1.81

11

3 100

3.94 50

1.97 52

2.05

26

Note: Dimension Z assumes that the drives are mounted side-by-side with no

clearance.

Typical drive heat losses are 3% of operating load conditions.

Above are guidelines only and the operating ambient temperature of the drive

MUST be maintained at all times.

4. P

OWER

W

IRING

4.1. G

ROUNDING THE

D

RIVE

This manual is intended as a guide for proper

installation. ERIKS Industrial Services Ltd cannot

assume responsibility for the compliance or the non-

compliance to any code, national, local or otherwise,

for the proper installation of this drive or associated

equipment. A hazard of personal injury and/or

equipment exists if codes are ignored during

installation.

This drive contains high voltage capacitors that take

time to discharge after removal of main supply.

Before working on the drive, ensure isolation of main

supply from line inputs. Wait ten (10) minutes for

capacitors to discharge to safe voltage levels. Failure

to observe this precaution could result in severe

bodily injury or loss of life.

Only qualified electrical personnel familiar with the

construction and operation of this equipment and the

hazards involved should install, adjust, operate, or

service this equipment. Read and understand this

manual and other applicable manuals in their entirety

before proceeding. Failure to observe this precaution

could result in severe bodily injury or loss of life.

Use the dedicated ground terminal to ground the

drive. Do not use mounting screws/bolts or chassis

screws for grounding

4.1.1. G

ROUNDING

G

UIDELINES

The ground terminal of each Fenner drive should be

individually connected DIRECTLY to the site ground busbar.

Fenner drive ground connections should not loop from one

drive to another, or to, or from any other equipment. Ground

loop impedance must confirm to local industrial safety

regulations. To meet UL regulations, UL approved ring crimp

terminals should be used for all ground wiring connections.

The drive Safety Ground must be connected to system

ground. Ground impedance must conform to the requirements

of national and local industrial safety regulations and/or

electrical codes. The integrity of all ground connections should

be checked periodically.

Ground Fault Monitoring

If a system ground fault monitor is to be used, only Type B

devices should be used to avoid nuisance tripping.

Drives with an EMC filter have an inherently higher leakage

current to Ground (Earth). For applications where tripping

occurs the EMC filter can be disconnected by removing the

EMC screw on the side of the product.

The Fenner QD product range has input supply voltage

surge suppression components fitted to protect the drive

from line voltage transients, typically originating from

lightening strikes or switching of high power equipment

on the same supply.

When carrying out a HiPot (Flash) test on an installation in

which the drive is built, the voltage surge suppression

components may cause the test to fail. To accommodate

this type of system HiPot test, the voltage surge

suppression components can be disconnected by

removing the VAR screw. After completing the HiPot test,

the screw should be replaced and the HiPot test repeated.

The test should then fail, indicating that the voltage surge

suppression components are once again in circuit.

Safety Ground

This is the safety ground for the drive that is required by

code. One of these points must be connected to adjacent

building steel (girder, joist), a floor ground rod, or bus bar.

Grounding points must comply with national and local

industrial safety regulations and/or electrical codes.

Motor Ground

The motor ground must be connected to one of the

ground terminals on the drive.

Shield Termination (Cable Screen)

The safety ground terminal provides a grounding point for the

motor cable shield. The motor cable shield connected to this

terminal (drive end) should also be connected to the motor

frame (motor end). Use a shield terminating or EMI clamp to

connect the shield to the safety ground terminal. When shielded

cable is used for control and signal wiring, the shield should be

grounded at the source end only, not at the drive end.

4.2. W

IRING

P

RECAUTIONS

Connect drive according to section 4.3 Connection Diagram,

ensuring that motor terminal box connections are correct.

There are two connections in general: Star and Delta. It is

essential to ensure that the motor is connected in accordance

with the voltage at which it will be operated. For more

information, refer to section 4.5 Motor Terminal Box

Connections. For recommended cabling and wiring sizing,

refer to section 10.2 Rating tables. It is recommended that the

power cabling should be 3-core or 4-core PVC-insulated

screened cable, laid in accordance with local industrial

regulations and codes of practice.

NOTE

Fenner QDE User Guide 9/5/08 9:23 AM Page 7