11

EN

2.4

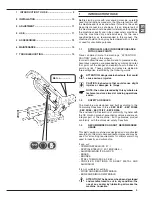

POSITION/WORK STATION (Fig.3)

Place the machine on a sufficiently flat workbench so that

the machine has the better possible stability.

In respect of ergonomic criteria during cutting operations,

the workbench must be positioned at such a height that the

clamp level is between 90 and 95 cm from the ground

(see

fig. 3)

.

ATTENTION: Make sure that the machine is placed

in a working area with suitable environmental

conditions and lighting. The general conditions

of the working environment are of fundamental

importance for accident prevention.

2.5

ELECTRICAL CONNECTIONS

Check that the mains to which the machine is connected is

earthed in accordance with current safety regulations and

that the power point is in good condition.

Remember that there should be a magnetothermic

protective device fitted upstream of the mains to protect

all the conductors from short circuits and overloads.

This protective device should be selected according to the

electrical features of the machine listed below:

Nominal voltage .............................................. 230 Volt ~

Nominal frequency ....................................... 50/60 Hertz

Max programmed absorbed value ................... 2000 Watt

Nominal input power ........................................ 1200 Watt

Power factor ............................................................. 0,96

Nominal speed ................................... 11.000-23.000 rpm

Insulation ........................................................... Classe B

Type of service ............................. intermittent S4-60 %

In case of power failure in mains, while you wait for

power to be restored there is no danger hazard may

arise: in fact, the electronic governor O (Fig. 7) is also

equipped with a reset function which prevents the

machine from restarting automatically.

The motor of your sawing machine is equipped with a

protective heat circuit breaker which interrupts the

power supply when the temperature of the coils rises

too high.

When the power supply is interrupted, wait for normal

reset.

3

ADJUSTING (Fig. 4-5-6-7-8)

3.1

TENSION OF THE BLADE (Fig.4)

ATTENTION: The machine is fitted with a blade-

tightening device that limits tension

automatically.

Turn handwheel

B

clockwise until the clutch engages

3.2

BAR STOP (Fig.5)

Use the bar stop supplied if you have to do several cuts

on pieces of the same length.

In this way you do not have to repeat the same

measurement each time.

Screw rod

E

into the hole of the base and fasten it with nut

F.

Slacken the handwheel

G

and place the stop

L

at the

correct distance from the blade. Tighten handwheel

G

again.

3.3

CUTTING ANGLE (Fig.6)

To performe a cut at 45, slacken the two knobs

M

and

rotate the body to the left until it rest on stop

N

, whose

position was calibrated during the final inspection.

For all the other intermediate angles, match the indicator

of the swivel supporto with the respective position on the

plate

O.

3.4

CUTTING SPEED (Fig.7)

Your sawing machine is equipped with CESC (Constant

Electronic Speed Control), which allows gradual and

continuous variation of the cutting speed, adapting it to the

type and dimension of the material to be cut (see CUTTING

TABLE ).

To select the most suitable speed, use the speed control

knob

O

to increase or decrease the speed as you require.

3.5

SLIDING BLADE GUIDE (Fig. 8)

The sliding blades guide

P

with integrated protection fitted

on your sawing machine is used to perform the cut while

guiding the necessary part of the blade and fully protecting

the part not used in the cutting process.

Slacken the knobs

Q

and slide the blades guide

P

so as to

move it closer to or further from the part to be cut, as

shown in the figure.

ATTENTION: If this adjustment is not done, the

part of the blade not used in the cutting process

will be exposed and this will create an extra

risk of contact, besides altering the quality of

the cut.

3.6

BEARINGS BLADE GUIDE (Fig.9)

The blade-guide on the outside of the sawing machine are

eccentric and adjustable so as to simplify blade replacement

and to keep it guided as its best.

They must always touch the blade slightly, so that they

rotate when the blade passes, but must not be completly

locked.

In order to approach or remove the eccentric blade-guide,

gently turn the head of the screws

R

using a 10 mm.

wrenches key.

4

USE

4.1

RUNNING IN THE BLADE

ATTENTION: If the correct running in procedure

is not performed, the bladès cutting precision

may be irreparably compromised.

To obtain the best performance, the bi-metal blades fitted

on your sawing machine must be run in for a short period.

For this reason the first two or three cuts should be done

where possible on a solid piece Ø 40-50 mm, using a very

slight pressure on the blade, and gradually increasing

pressure in subsequent cuts.

To gauge the correct pressure in normal operating conditions

defined by this manual (see cutting table), consider for

example that the first cut on solid steel (eg. C40) Ø 50 mm

should be done in about 4 minutes.