13

EN

4.6

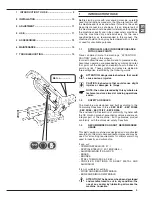

CORRECT POSITIONING OF THE PIECE IN

THE CLAMP (Fig. 11)

The pieces to be cut should be fitted directly between the

jaws without adding other objects.

ATTENTION: Never hold the pieces to be cut in

your hand.

(Fig. 11)

When the pieces to be cut are profiled sections, flat pieces

or special shapes, refer to the examples shown in the

figures.

If the thickness of the profiled section is to be very thin,

an outline should be fitted which copies the profile inside

the profiled section itself to stop it being crushed between

the jaws.

4.7

CUTTING TABLE

5

ACCESSORIES

5.1

CHOISE OF BLADE

Your sawing machine is equipped with a bi-metal blade

measuring 1735x13x0,9 mm with variable toothing 6/10

teeth per inch, for use in the majority of cuts possible with

this machine. For special requirements (see cutting table

point 4.7), for example, for cutting large solid sections or

profiled sections or corner pieces of small thickness, there

are also blades avail-able with 4/6 toothing or 14 teeth per

inch.

MATERIAL:..............M42 (steel for springs ÷ steel HSS)

EXTENSION: .............................................. mm 1735

HEIGHT: .........................................................mm 13

THICKNESS: .................................................mm 0,9

TOOTHING: ..........................................standard 6/10

optional 4/6 - 14

5.2

FITTING THE BASE PLATE (Fig. 3)

(where included)

The fasten the machine to the base plate, use the four

screw

A

, four nuts

B

and four Washer

C

conteined in yhe

carton box of the base plate.

Put the four screws

A

into the holes of the base of the

machine, and fasten the whole with the four nuts

B

.

6

MAINTENANCE

6.1

REGULAR MAINTENANCE

The operations of ordinary maintenance, which may also

be performed by non-specialist personnel, are all described

in the previous sections and here below.

1. Before performing any maintenance operation,

disconnect the machine electric plug from the wall

outlet.

2. During maintenance operations, always wear personal

protection (safety goggles and gloves).

3. Remove the processing residues from the cutting

area and the blade guides whenever necessary.

You are advised to use a suction device or a brush.

ATTENTION: Do not use jets of compressed air

.

If you do not intend to use the sawing machine for a long

time, clean it and put it in a dry place if possible.

In these cases it is advisable to slacken off the blade so

that it is not kept tight for no reason.

6.2

ASSISTENCE

Should it be necessary to call qualified personnel for

operations of extraordinary maintenance, or in the case

of repairs, under guarantee or at a later date, you should

always contact an authorized service centre or the factory

directly, if there is no service centre in your area.

6.3

DISPOSAL OF THE MACHINE, PACKING

At the end of the machine life, if the

machine must be scraped, contact

an authorised waste disposal centre

in order to comply with the Standards

for hygiene and environment

safeguard.

The packing must be disposed of

according to the ruling standards by

delivering it to authorised people for

the collection, disposal or reclaim.

Please contact the ASSOCIATION OF USED OILS near

to you.

2002/96/EC