12

EN

After running-in, the same piece may easily be cut in

about 2 minutes. If the running-in process is done correctly,

the finish and precision of the cut will be of better quality

and the blade will last longer.

4.2

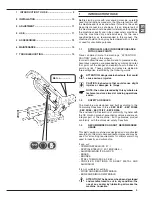

WORKING (Fig. 7)

Turn the main switch

D

to position

1

: in doing the switch

comes on and the machine is ready for operation.

ATTENTION: Before starting any cutting

operation, check that all the protections are

complete and in the correct position.

Once you have completed all the procedures and operations

described so far, you may start the working processes.

To perform the cut, move to the front of the machine and

grip the handgrip with your right hand.

ATTENTION: Keep your left hand away from the

cutting area and on no account try to reach it

when cutting is in process.

Use your right-hand thumb to press the side release button

B (Fig. 7)

: as such you will disable the safety system

that prevents any unintentional starts. Then use your right-

hand forefinger to press start button A and lower the body

gradually until the blade lightly touches the work piece to

be cut.

Now begin to apply gradual pressure on the part and

complete the cut.

ATTENTION: Always release button

A

between

one cutting operation and another, while you

are positioning the part. do not try to block it

or alter its functional characteristics in any

way.

If the machine suddenly stops after numerous

consecutive cuts, do not be alarmed. The heat protector

device of the motor has been activated, breaking the

power supply when the temperature of the coils

reaches the threshold limit defined by the insulation

class, to prevent damage to the motor.

In this case, release the button A and wait for automatic

reset which usually takes place after a few minutes.

Your sawing machine is equipped with an electronic

speed governor which also includes a motor

protection function obtained by means of an

amperometric limiter. In this way it can not absorb an

amount of current greater than the set one, expressed

by the maximum value of absorption (see 2.5).

If the limiter trips while the machine is in operation,

slightly decrease the cutting pressure in addition,

this enables to safeguard the blade life and

performance and to obtain always a sharp and clean

cut.

4.3

REPLACING THE BLADE (Fig. 9)

CAUTION: When you perform this operation,

always wear protective gloves to avoid contact

with the teeth of the blade.

- check that the main switch

D (Fig. 7)

is at position

0

;

- slacken the handles

Q

and slide the blades guide

P

as far

as it will go, following the direction on the arrow

(Fig. 8)

;

- remove the protective casing unscrewing the four screws;

- slacken the blade tension, turning the handwheel

B

in a

anti-clockwise direction

(Fig. 4)

;

- extract the blade first from the guides and then from the

rubber coated pulleys;

- insert the new blade first between the guides and then

onto the rubber coated pulleys,

with the teeth facing as

showed in (Fig. 9)

;

- put the blade under tension again as described in point

3.1.

- replace the protective casing;

- reposition the blade guides

P

in the correct position for

the next cut.

ATTENTION: This machine has been developed

for working with the blade rotating clockwise

(Fig. 9).

It is absolutely necessary to check that the blade

is produced according to this rotation mode.

4.4

CUTTING CAPACITY (Fig.10)

The table below specifies the cutting capacity at 0, 45

degrees which may be obtained in normal conditions of

use described in this manual and without placing any other

object between the jaws of the clamp.

0° = Ø 150 mm; 150 mm; 160x140 mm

45° = Ø 100 mm; 100 mm; 120x110 mm

4.5

USING THE VICE (Fig. 1)

The chuck of the saw is of the quick sliding type so that

the slider easily and rapidly approaches the pieces to be

locked.

To lock the piece to be cut in the chuck:

•

place yourself in front of the machine;

•

release the lever

3

towards the piece to be cut by

unlocking vice part

13

•

position the slider at a few millimetres from the

piece to be cut;

•

move the

3

towards the piece and lock it;

•

turn lever

12

clockwise so as to definitely lock the

piece between the jaws.

If more pieces of the same bar are to be cut, you only

need to unlock and then re-lock the chuck by means of

lever

12

.

If you need, instead, to change the bar, turn the lever

12

counterclockwise to unlock the chuck and then pull lever

3

towards you so that the slider moves away from the piece.