10

EN

1.4

STANDARD SAFETY PROCEDURS

- Do not use the machine in very damp places or in the

presence of inflammable liquids or gases.

- Do not use it in the open air when general weather and

environmental conditions are unfavourable (eg. explosive

atmospheres, during a storm or rain).

- Wear suitable clothes, without wide sleeves or articles

such as scarves, chains and bracelets which could get

caught in the moving parts.

- Always use personal protection devices: protective

goggles as recommended by safety standards, gloves

of the right size, headphones or earplugs, and hairnets if

necessary.

- Use the tools recommended in this manual if you want to

achieve the best performance from your sawing machine.

- Any power cable extensions must be type approved and

comply with safety standards.

- Avoid using the machine if your psycho-physical

condition are precarious or upset.

1.5

SAFETY PROCEDURS FOR FURTHER RISK

- Always keep processing residues away from the cutting

area.

- Always use the clamp. The parts to be cut must always

be held firmly in the clamp.

- Always keep hands away from the working areas while

the machine is moving: before loading or unloading the

part, release the run button on the hand grip.

- Do not force the machine unnecessarily : excessive

cutting pressure could cause rapid wear to the blade and

negatively influence the performance of the machine in

terms of finishes and cutting precision.

1.6

NOISE CONDITIONS

In normal conditions of use as described in this manual,

this belt sawing machine determines an equivalent level of

acoustic pressure:

Leq = 79,0 dB (A) when operating unloaded

Leq = 81,2 dB (A) during processing (eg. cutting of a steel

tube D. 130 mm thickness 10 mm), at cutting speed of 70

mt/min. with a weighted operating cycle of 2 minutes.

The frequency root mean RMS weighed for hand-arm

acceleration does not exceed 2.5m/s².

Measurement were obteined in compliance with UNI

7712, ISO 3740, ISO 3746 and CEE 89/392 regulation.

NOTE: Personal hearing protention should be

used, such as headphones or earplugs.

1.7

INFORMATION ABOUT THE

ELECTROMAGNETIC COMPATIBILITY

The European regulations on safety and, in particular, the

EEC Directive 89/336 contemplate that all the equipment

be equipped with shielding devices against radio

interferences both from and towards the outside.

This machine is equipped with filters through which the

machine is safe and in compliance with above regulations.

Tests were carried out according to EN 55011, EN

55014, EN 50082-1, IEC 1000-4-2, IEC 1000-4-4

regulations.

1.8

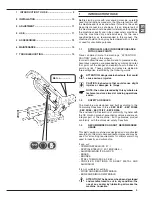

DESCRIPTION OF THE MACHINE (Fig. 1)

The belt sawing machine consists of two basic parts: the

machine body

5

complete with motor and drive

7

which is

integrated into lower part, consisting of the clamp

11

, the

base

13

and swivel support

9

.

Here is a list of the main parts with the number indicating

it in the drawing.

Legend

Fig. 1

1

Grip

2

Blade tension handwheel

3

Vice speed-slide drive

4

Sliding blade guide

5

Machine body

6

Blade

7

Motor

8

Control box

9

Bar stop

10

Clamp (vice)

11

Morsa

12

Clamp drive

13

Base

14

Handle for handling

WEIGHT

= 35 Kg.

SIZE

=

cm 1080 x75xH80 in maximum overall dimensions.

PACKAGING SIZE

= cm 100 x 39 x H57

2

INSTALLATION

2.1

REMOVING THE PACKING

Remove the wooden frame which protects the machine

during transit.

Try not to damage the frame as you may have to move

the machine long distances or store it for long periods.

2.2

HANDLING (Fig. 2)

As the machine is considerably heavy (35 kg net), it

needs at least 2 people to lift it, positioned on either side.

The machine must be lifted and transported by the handle

14

fixed on the base plate.

2.3

TRANSPORT (Fig.2)

Before moving the machine from one place to another by

lifting it, apply the two handles

14

attached to the base.

Take the handles and fix them with the screws and the nuts

on both sides of the base of machine.

It is necessary to low the saw body till the lower position

and fix it to the base; then you can proceed with the

trasport by lifting the machine by two person moving it at

the handle. Should the machine be fixed on a base plate

(column) unlock the screws first.

For trasport the machine, it is better to place in the box it

was when purchased. Ensure it is placed in the correct

position indicated by the arrows on the packaging.

Pay careful attention to the ideogram printed on the box as

they provide all necessary information for palletization

and stacking af boxes.

Tying the load down with ropes or safety belts is

raccomended during trasportation to prevent the load from

sliding or falling.