Doing so could cause injury associated with objects being drawn into the rotating parts.

DO NOT refuel a running engine or an engine that is hot.

Before using, always visually inspect to see that fasteners are secure, the housing is

undamaged and that guards and screens are in place. Replace worn or damaged

components in sets to preserve balance. Replace damaged or unreadable labels.

Before starting the machine, make certain that the tube is empty.

Keep your face and body away from the nozzle.

Do not allow hands or any other part of the body or clothing inside the discharge chute or

near any moving part.

Keep proper balance and footing at all times. Do not overreach. Never stand at a higher

level than the base of the machine when blowing material with it.

Always stand clear of the discharge zone when operating this machine.

To reduce the risk of hearing loss associated with sound level, hearing protection is required.

To reduce the risk of injury associated with contacting rotating parts, stop the engine before

installing or removing attachments. Do not operate without guard in place. Always disconnect

the spark plug before performing maintenance or accessing any movable parts.

Do not point the blower nozzle in the direction of people or pets.

Never run the unit without the proper equipment attached. When used as a blower, always

install the blower tubes.

operate the machine only at reasonable hours

– not early in the morning or late at night when

people might be disturbed;

Do not to operate the machine near open windows.

use rakes and brooms to loosen debris before blowing

slightly dampen surfaces in dusty conditions or use mister attachment;

Limit the time of use of the tool. Take a time of rest between 2 operations. Do not work earlier

or later in the night. Do be exposed to noise and vibration for a prolonged time. Noise can

bring damage to the ears.

This machine is extremely noisy. Always wear a hearing protection when use the tool.

In the event of accident or breakdown, stop to use the machine. Switch off the tool and wait

until it completely stops. Check the problem. In case of blockage, clear the blockage carefully.

In case of breakdown, bring the tool to an after sales service for inspection and reparation.

Only use the tool when it is safely unblocked.

operate the machine only at reasonable hours

– not early in the morning or late at night when

people might be disturbed;

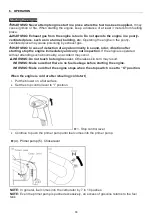

WARNING

– there is danger from rotating parts; do not enter in contact with them.

Maintenance and storage

When the machine is stopped for servicing, inspection, or storage, or to change an accessory,

shut off the power source and make sure that all moving parts have come to a complete stop.

Allow the machine to cool before making any inspections, adjustments, etc. Maintain the machine

with care and keep it clean.

Store the machine in a dry place out of the reach of children.

Always allow the machine to cool before storing.

Replace worn or damaged parts for safety. Use only genuine replacement parts and

accessories.

Never attempt to override the interlocked feature of the guard.

Residuals risks

Even if you use this product in compliance with all safety requirements, potential risks of injury and

damage remain. The following hazards may arise from the structure and design of this product.

Always be vigilant when using this product, so you can recognize and manage the risks early.

Rapid intervention can prevent serious injury and property damage. Turn off the tool if there are

any malfunctions. Have it checked by a qualified professional and have repairs carried out, if

5

Summary of Contents for FSDT75

Page 25: ...NOTES 25 ...

Page 26: ...NOTES 26 ...

Page 27: ...NOTES 27 ...

Page 28: ...BUILDER SAS 32 rue Aristide Bergès ZI 31270 Cugnaux France Made in PRC 2021 ...