IMPORTANT

The servicing of a tool with double insulation requires extreme care and knowledge of the system

and should be performed only by a qualified service technician. For service, we recommend that

you return the tool to our authorized Service Center for repair.

ALWAYS use original factory replacement parts when servicing.

EXTENSION CORDS

The use of any extension cord will cause some loss of power. To keep the loss at a minimum and

to prevent overheating, use an extension cord that is heavy enough to carry the current that the

tool will draw.

PROBLEM SHOOTING

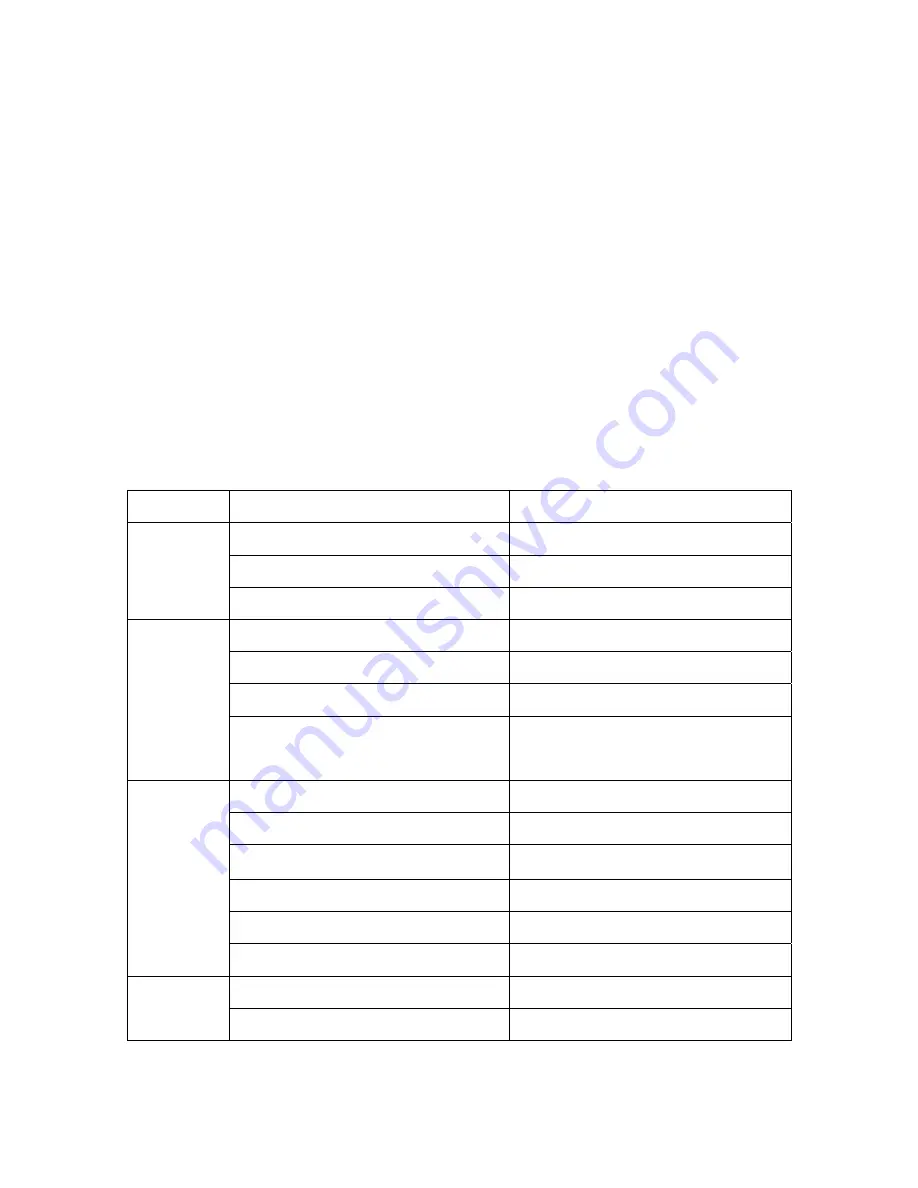

PROBLEM CAUSE

SOLUTION

1. Damaged teeth

1. Replace blades

2. Feed speed is too fast

2. Reduce the feed speed

An unusually

large amount

of sparks

3. Blunt teeth

3. Replace blade pack

1. Feed speed is too fast

1. Reduce the feed speed

2. Damaged teeth

2. Replace blade pack

3. Blunt teeth

3. Replace blade pack

A lot of wear

in sections

4. Not cutting parallel or

perpendicular to work surface

4 Hold saw parallel to work surface

1. Damaged teeth

1. Replace blade pack

2. Feed speed is too fast

2. Reduce feed speed

3. Speed selected so high

3. Lower the speed grade

4. Blunt teeth

4. Replace blade pack

5. Blades have buckled

5. Replace blade pack

Blades are

breaking

6. Blades have burned out

6. Replace blade pack

1. Teeth badly broken or worn off

1. Replace blade pack

Blades Split

off

2. Blunt teeth

2. Replace blade pack

19

Summary of Contents for FDL125

Page 21: ...Optional Accessories 1 Base Plate with Guide Ruler 2 Laser Guide Indicator 21...

Page 22: ...3 Sliding Guide Plate 22...

Page 24: ...24...

Page 25: ...RUBBER 25...