switch tables 3-2 through 3-4. See Section 5 Service and

Maintenance for board access procedures. Once patterns

are chosen for each of the program inputs, then the pro-

gram inputs are assigned to a slide switch position.

The default program inputs assigned to a slide

switch position, along with the default pattern for each

program input are as follows:

•

Slide switch position #1 – P1, Rear Flashing

•

Slide switch position #2 – P2, Rotate 90 FPM

•

Slide switch position #3 – P2, Rotate 90 FPM

To assign a different Smart Pod program input to a

slide switch position perform the following:

A. Disconnect power to the lightbar. If the cover

is removed, this can be accomplished by removing the

10GA RED power wire from the relay.

B.

Apply 12VDC to the WHT/YEL and WHT/

BLK control wires.

C.

Apply power to the lightbar (reconnect the

RED 10GA power wire.)

D. The right upper LED module in POD #4 will

light indicating the bar is in Smart Pod programming

mode.

E. Move the slide switch to the desired position.

The following will be displayed for each slide switch po-

sition:

1.

Slide Switch #1 – Front LED module

POD #1 and the Smart Pods will operate according to

the stored program input.

2.

Slide Switch #2 – Front LED module

POD #1,the upper LED module POD #1 and the Smart

Pods will operate according to the stored program input.

3.

Slide Switch #3 - Front LED module

POD #1,the upper LED module POD #1,rear LED mod-

ule POD #1 and the Smart Pods will operate according

to the stored program input.

F.

Remove 12VDC from the WHT/BLK control

wire. Momentarily re-apply 12VDC to the WHT/BLK

control wire and the Smart Pods will advance to the

next program input. Each time 12VDC is momentarily

applied to the WHT/BLK control wire the program num-

ber will advance. When the last available program num-

ber is reached the next operation will select the first

available program, which is OFF.

G. If programs assigned to the other slide switch

positions are to be changed, move the slide switch to the

desired position and repeat the above steps.

-5-

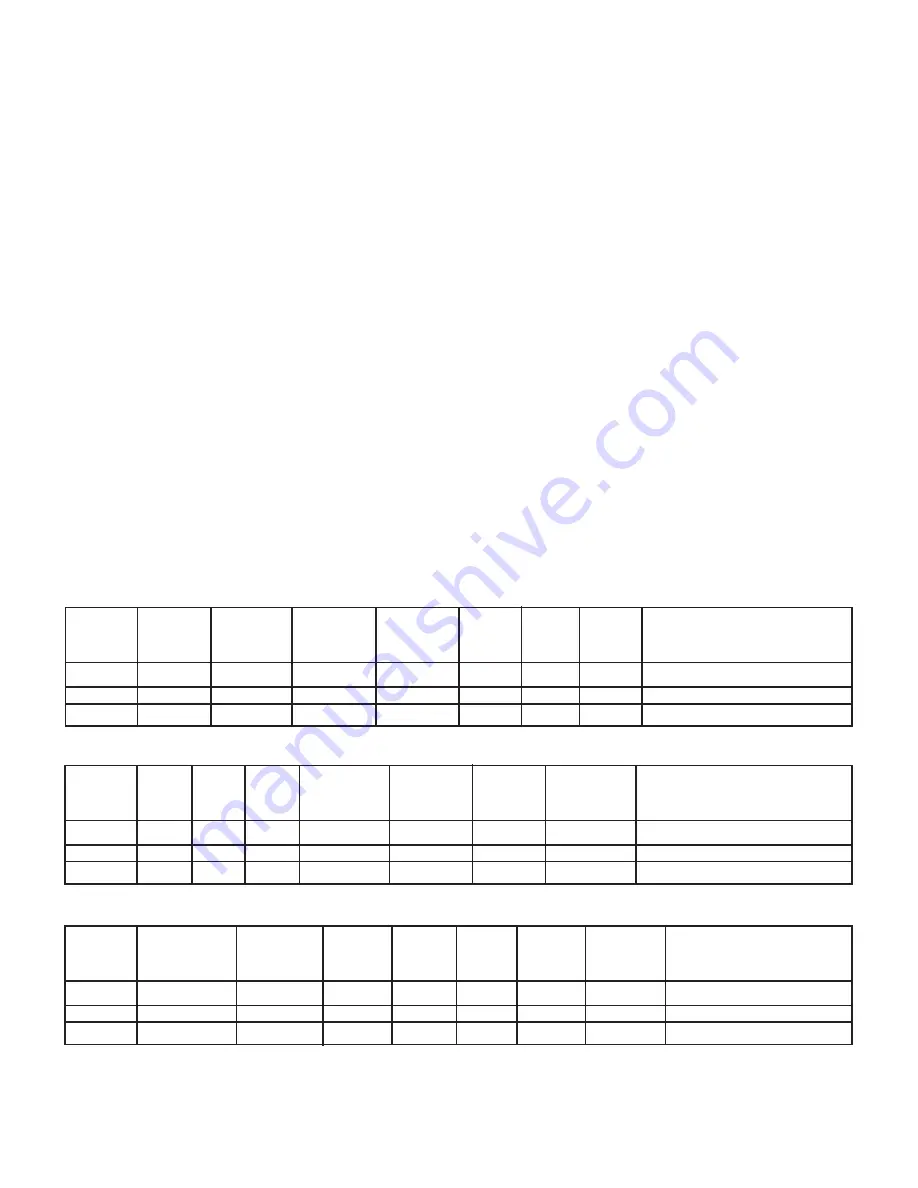

Table 3-2

P1

Rear

Oscillating Oscillating Oscillating Rotate

Rotate Rotate

Front

Switches Flashing* Rear

Intersection Front

90

120

175

Flashing

(S2)

FPM

FPM

FPM

P1A

OFF

ON

OFF

ON

OFF

ON

OFF

ON

P1B

OFF

OFF

ON

ON

OFF

OFF

ON

ON

P1C

OFF

OFF

OFF

OFF

ON

ON

ON

ON

Table 3-3

P2

Rotate Rotate Rotate Oscillating

Oscillating Front

Oscillating

Rear

Switches 90

120

175

Intersection Front

Flashing Rear

Flashing

(S2)

FPM* FPM

FPM

P2A

OFF

ON

OFF

ON

OFF

ON

OFF

ON

P2B

OFF

OFF

ON

ON

OFF

OFF

ON

ON

P2C

OFF

OFF

OFF

OFF

ON

ON

ON

ON

Table 3-4

P3

Oscillating

Oscillating Rotate

Rotate Rotate Front

Oscillating Rear

Switches Intersection* Front

175

120

90

Flashing Rear

Flashing

(S1)

FPM

FPM

FPM

P3C

OFF

OFF

OFF

OFF

ON

ON

ON

ON

P3B

OFF

OFF

ON

ON

OFF

OFF

ON

ON

P3A

OFF

ON

OFF

ON

OFF

ON

OFF

ON

* Factory Setting

Summary of Contents for SMART VECTOR SL

Page 12: ......