179

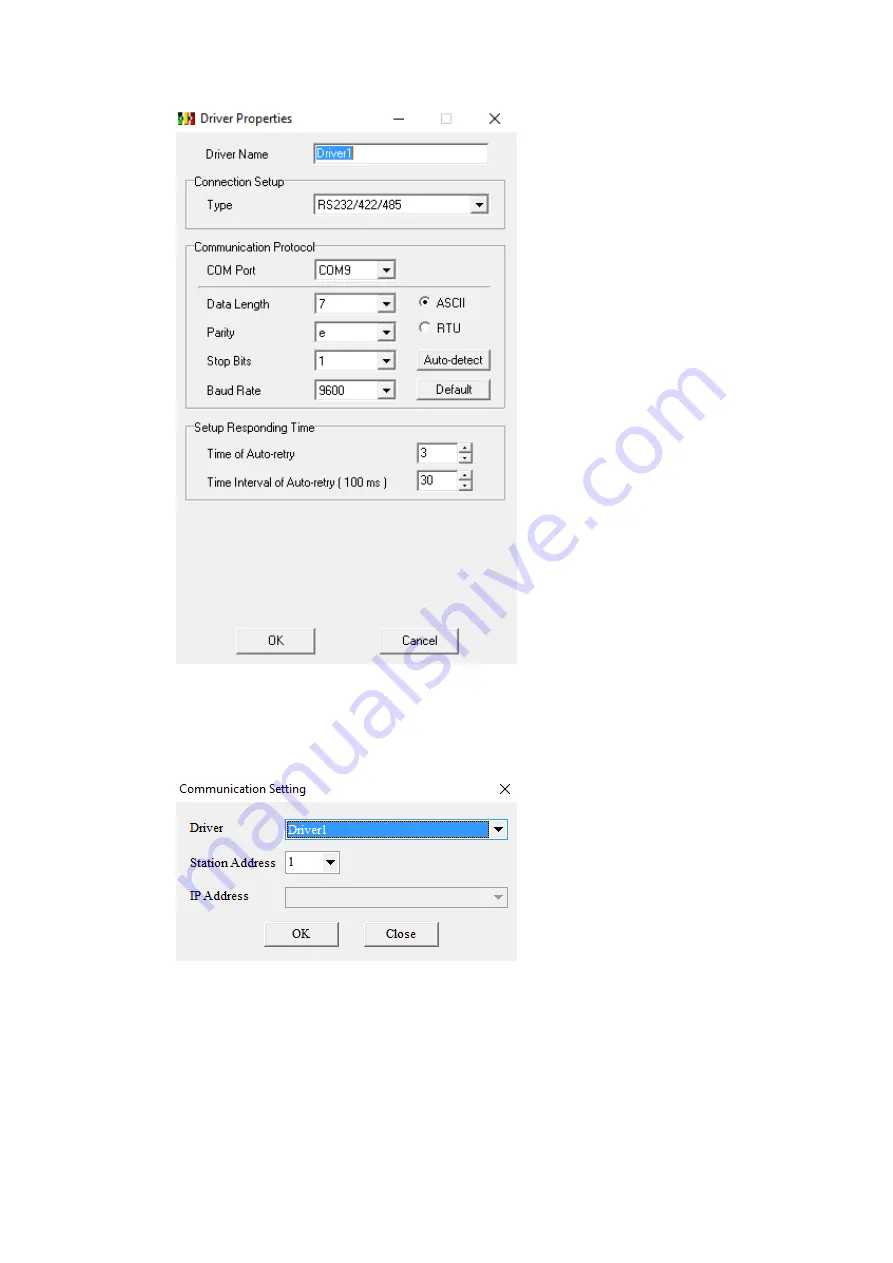

In ISPSoft, under the Tools menu option, select Communication Settings. Select the

name of the connection configured in COMMGR and press OK.

Under the PLC menu option, select Transfer and Upload. If there is a program on the

PLC, it will be uploaded and the system settings can be configured. If there is no

program present on the PLC one will have to be downloaded.

Summary of Contents for P5 Series

Page 1: ...1 P5Series ...

Page 53: ...53 Note For more detailed information please refer to the PLC manual Connecting PLC to HMI ...

Page 93: ...93 Note For more detailed information please refer to the PLC manual HMI 設定 ...

Page 116: ...116 In the dialog window the IP address can be changed Press OK to confirm the setting ...

Page 124: ...124 Note For more detailed information please refer to the PLC manual Connecting PLC to HMI ...

Page 149: ...149 Note For more detailed information please refer to the PLC manual Connect PLC to HMI ...

Page 152: ...152 Note For more detailed information please refer to the PLC manual Connecting PLC to HMI ...

Page 158: ...158 Note For more detailed information please refer to the PLC manual Connect PLC to HMI ...

Page 161: ...161 Note For more detailed information please refer to the PLC manual Connecting PLC to HMI ...

Page 200: ...200 Note For more detailed information please refer to the PLC manual Connecting PLC to HMI ...

Page 220: ...220 2 choose model and build project click PLC on the top select connect to connect ...

Page 221: ...221 connect success as shown below HMI Setting ...