7.6. Push Motion

85

www.fastech.co.kr

3) Setting Method

This function is

working only in absolute position value

. The position error can happen due to the

work status in push mode. Push motion command can be executed by 2 methods. One is RS-485

communication(DLL library) method and the other is external digital signal(PT Start command)

method.

DLL library method

The following table shows the setting conditions and refer to

「

User Manual

– Communication

Function

」

.

There is another library for status checking of push motioning. The position value that is

used in push motion must be

‘absolute coordinate’ value.

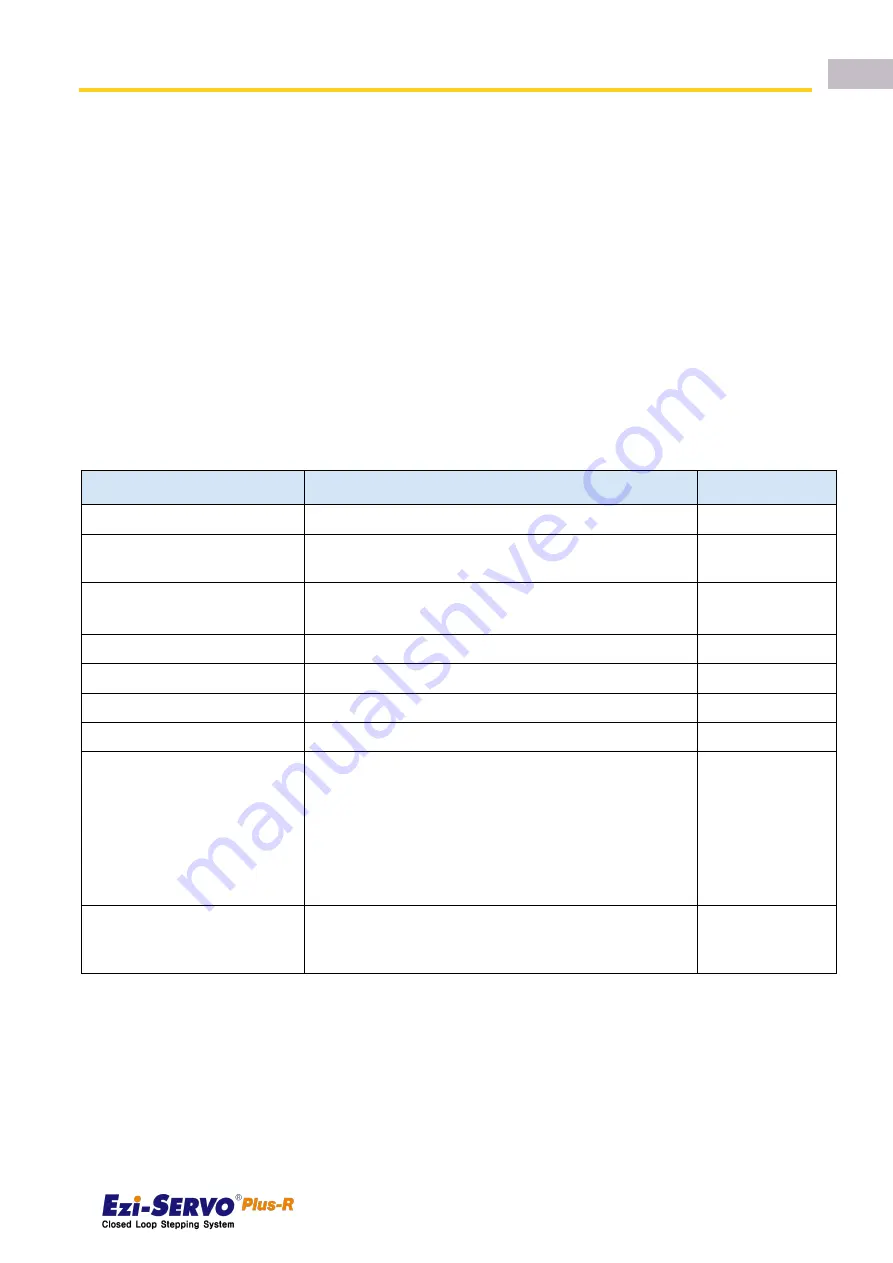

Setting Item

Description

Range *1

Position command Start speed

Start speed value of position motion

1~35000[pps]

Position

command

Moving

speed

Moving speed of position motion

1~500000[pps]

Position

command

Target

position

Absolute target position value of position command

134,217,727 ~

134,217,727

Acceleration time

Acceleration time of position motion

1~9,999[ms]

Deceleration time

Decelerate time of position motion

1~9,999[ms]

Push ratio

Motor torque value in push mode

20~80[%]

Push command Moving speed

Moving speed of Push motion (max 400[rpm])

1~66000[pps]

Push command Target

position

Absolute targett position value of push command.

*Non-stop mode : the value must be set more than

‘ Position command Target position’ value.

*The motor will stop if the position is exceed this value

even if the work is not detected.

134,217,727 ~

134,217,727

Push mode

Set Stop mode(0) or Non-stop mode(1~10000) after the

work detect. In case of Non-stop mode, the motor move

backward as much as this value[pulse] distances.

0~10,000

*1 : The unit of [pps] in this item is referenced to 10,000[ppr] encoder.

Input signal(PT Start) Method

Firstly the position table data must be entered before the push motioning and refer to

「

User

Manual

– Position Table Function

」

.

Summary of Contents for Ezi-Servo ALL

Page 1: ...www fastech co kr User Manual Text Ver 3...

Page 10: ...2 1 Driver Specification www fastech co kr 10 2 1 2 Ezi SERVO Plus R MINI...

Page 11: ...2 1 Driver Specification 11 www fastech co kr 2 1 3 Ezi SERVO ALL 28 series...

Page 12: ...2 1 Driver Specification www fastech co kr 12 2 1 4 Ezi SERVO ALL 42 56 series...

Page 13: ...2 1 Driver Specification 13 www fastech co kr 2 1 5 Ezi SERVO ALL 60 60 ABS series...

Page 17: ...3 2 Motor Dimension 17 www fastech co kr 3 2 Motor Dimension...

Page 18: ...3 2 Motor Dimension www fastech co kr 18...

Page 19: ...3 2 Motor Dimension 19 www fastech co kr...

Page 20: ...3 3 Motor Torque www fastech co kr 20 3 3 Motor Torque 3 3 1 Ezi SERVO Plus R...

Page 23: ...4 1 Part Numbering 23 www fastech co kr 3 Ezi SERVO ALL series...

Page 28: ...4 3 External Wiring Diagram www fastech co kr 28 4 3 2 Ezi SERVO Plus R 86mm...

Page 29: ...4 3 External Wiring Diagram 29 www fastech co kr 4 3 3 Ezi SERVO Plus R MINI...

Page 30: ...4 3 External Wiring Diagram www fastech co kr 30 4 3 4 Ezi SERVO ALL 28 series...

Page 31: ...4 3 External Wiring Diagram 31 www fastech co kr 4 3 5 Ezi SERVO ALL 42 56 series...

Page 32: ...4 3 External Wiring Diagram www fastech co kr 32 4 3 6 Ezi SERVO ALL 60 series...

Page 33: ...4 3 External Wiring Diagram 33 www fastech co kr 4 3 7 Ezi SERVO ALL 60 ABS...

Page 44: ...5 3 Ezi SERVO ALL 28 www fastech co kr 44 5 Network ID Setting 6 Connector Specifications...

Page 51: ...5 5 Ezi SERVO ALL 60 60 ABS series 51 www fastech co kr 8 Connector Specifications...