(2) MOBIL Mobilux EP2 lubricant grease

(3) Domestic No.2 industrial lithium base grease for extreme pressure.

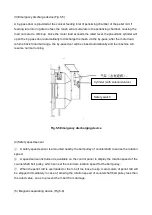

6.3.3 List of daily inspection items (prior to each running or each running)

No.

Position

Inspection item

Cycle

Method

Solution

1

Steam

Check whether the pressure is

above0.6Mpabefore pressure reducing

valve

Everyday

Inspection

Increase steam

pressure

Check whether the pressure is

about0.4Mpaafter pressure reducing

valve

Everyday

Inspection

Adjust pressure

reducing valve

Check for any leakage in the pipeline

Everyday

Inspection

Repair steam

pipeline

Check for normal operation of trap valve Everyday

Inspection

Clean steam

line

2

Machine

Check for any abnormal noise

Everyday

Listening

Checking

3

Pneumatic

by-pass

assembly

Make sure air supply is above 0.6Mpa

Everyday

Inspection

Adjust the air

pressure

4

Bearing

Check for temperature lower than45

℃

.

Everyday

Thermometer Checking

5

Motor

Check for temperature lower than45

℃

.

Everyday

Thermometer Checking

Check whether the current value is in

rated range

Everyday

Ammeter

Checking

Check for the level of lubricant grease

and if abnormal noise

Everyday

Inspection

Checking

6

Temperature

sensor

Check for normality

Everyday

Inspection

Replacing

7

Cutting knives

Check for abrasion state of cutter

Everyday

Inspection

Replacing

8

Ring die

Check if the conical surface is in place

Everyday

Inspection

Checking

Check onconditiona of die hole

Everyday

Inspection

Cleaning

check if centering pins, bolts of ring die

are working properly

Everyday

Inspection

Inspection,

replacement

9

Roller

Check on rollerfor shifting

Everyday

Inspection

Checking

Check for any abnormality of wearing

Everyday

Inspection

Checking

10

Tail locknut

Check for any loose

Everyday

Inspection

Checking