5 Running

5.1Instrucitons for operations

Note: When operation is implemented on the machine, besides the safety cautions specified in

Chapter 1, the regulation items of the owner's enterprise shall also be obeyed.

(1) Pay attention to the place where the dangerous signs are attached when operating.

(2) The safety protection devices can never be dismounted, covered or bypassed at will.

5.2Preparation work

Do the following before startup:

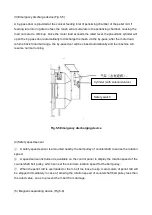

(1) Open the main door and adjust the distance between the pellet cutting knives and

the die’s outer surface;

(2)Clean the pelletizing chamber and check the feeder and conditioner;

(3)Check the ring die for correct installation and the press rollers for proper adjustment;

pay attention to the adjustment of the clearance between the press rollers and the ring

die;

(4)Fill up lubricants according to the lubrication diagram;

(5)Look at the oil level in oil box of hydraulic system if normal (if a hydraulic system is in

place).

(6)Start the hydraulic pump motor and check the manometer for proper pressure value.

On the first day of operation, these rated values should be checked in required intervals,

if necessary, readjustment is in need to make the reading correct (if a hydraulic system

is equipped).

(7)Start the feeder motor and the conditioner motor without load to check if each rotation

direction is correct and if any noise; and then shut them down at a low speed of feeder

motor.

(8)Start the main motors, firstly check and ensure that all components of the pellet mill

can work normally and the ring die rotates in clockwise viewing from the front side.Then